7075 Aluminum Material Property Data Sheet

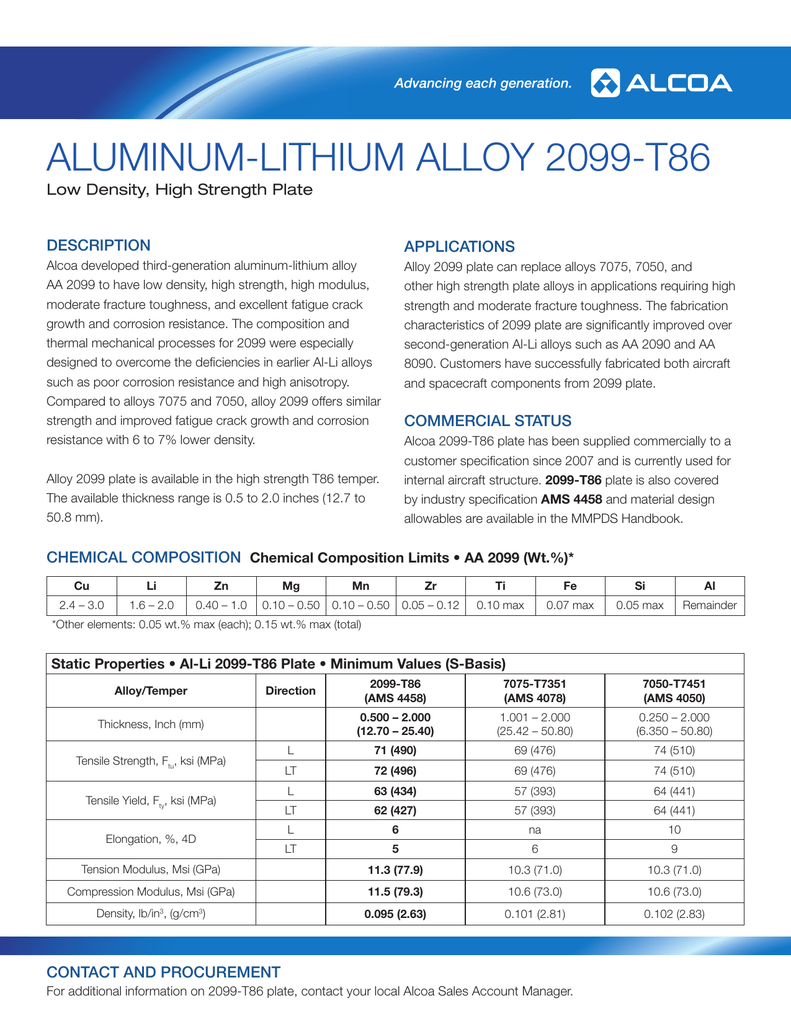

The superior stress corrosion resistance of the t173 and t7351 tempers makes alloy 7075 a logical replacement for 2024 2014 and 2017 in many of the most critical applications.

7075 aluminum material property data sheet. Alloy 7075 is a very high strength aerospace aluminium grade. A member of the 7000 series it is one of the strongest alloys available and is comparable to many types of steel. Nonferrous metal close analogs. Aluminium sheet coil plate alloy 7075 nb indd.

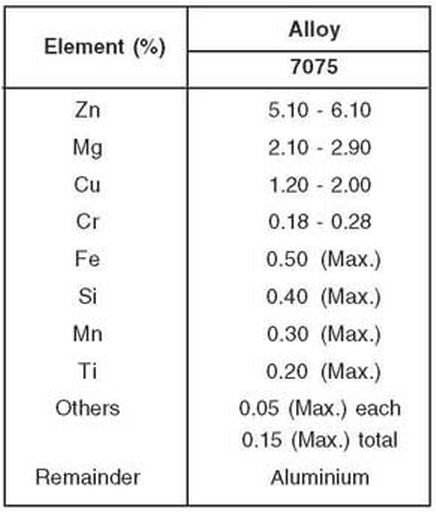

With zinc as it s primary alloying element it is exceptionally strong. Composition for aa 7075 not alclad 7075 specifically. It is produced in many tempers some of which are 7075 0 7075 t6 7075 t651. A zr ti limit of 0 25 percent maximum may be used with this alloy designation for extruded and forged products only but only when the supplier or producer and the purchaser have mutually so agreed.

Key features very high tensile and yield strength superior stress corrosion fair machinabiliy. Data points with the aa note have been provided by the aluminum association inc. 7075 aluminium alloy s composition roughly includes 5 6 6 1 zinc 2 1 2 5 magnesium 1 2 1 6 copper and less than a half percent of silicon iron manganese titanium chromium and other metals. The properties listed in this alloy data sheet represent the best current information for this alloy.

Very high strength material used for highly stressed structural parts. With zinc as the dominant alloying element the 7075 aluminium alloy also known as aircraft aluminium or aerospace aluminium was the first alloy of high strength composed by al zn mg cu that was able to successfully combine the perks of the inclusion of chromium to develop high stress corrosion cracking resistance in sheet products. Alclad aluminum 7075 t6 t651 categories. And are not for design.

The t6 and t651 tempers have fair machinability. Consult the material safety data sheet msds for proper safety and handling precautions when using alloy 7075. The t7351 temper offers improved stress corrosion cracking resistance. Machinability of 7075 is rated as fair.

Aluminium alloy 7075 aluminium alloy 7075 offers the highest strength of the common screw machine alloys. Alloy selection is important for extrusion projects and in the aerospace industry the 7075 aluminum alloy is commonly used. In each specific application the user is expected to evaluate and test the alloy temper and finishing method. Physical properties characteristic imperial metric normal density 68 f 20 c.

General 7075 characteristics and uses from alcoa. 7000 series aluminum alloy.