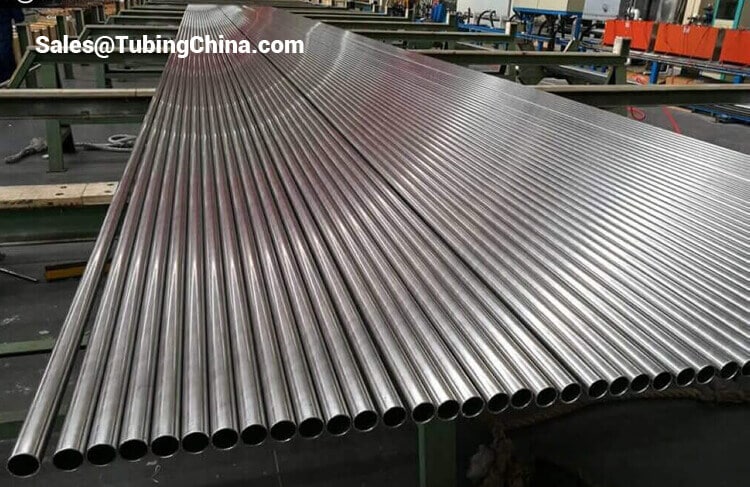

316l Stainless Steel Data Sheet

It is often utilized in process streams containing chlorides or halides.

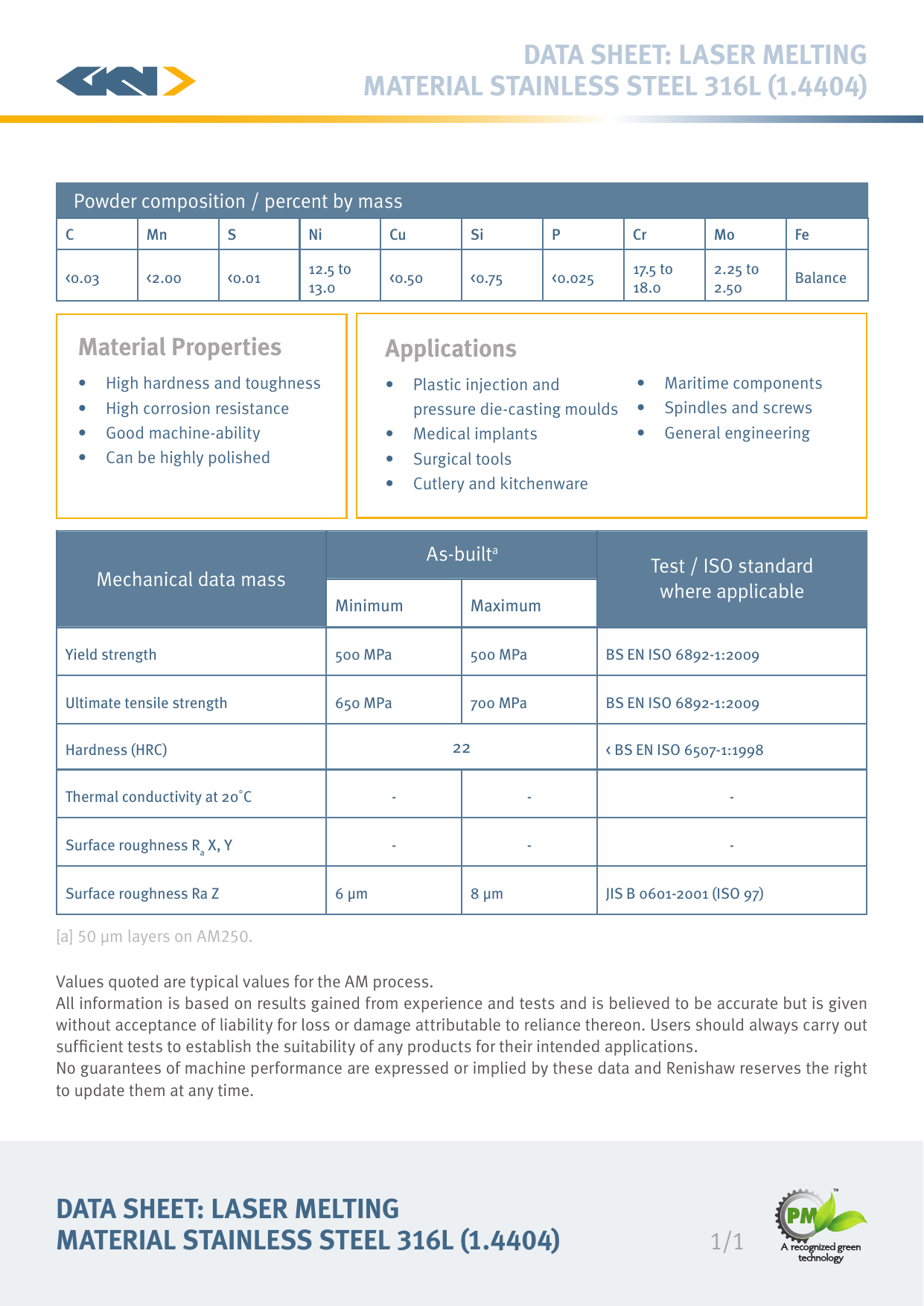

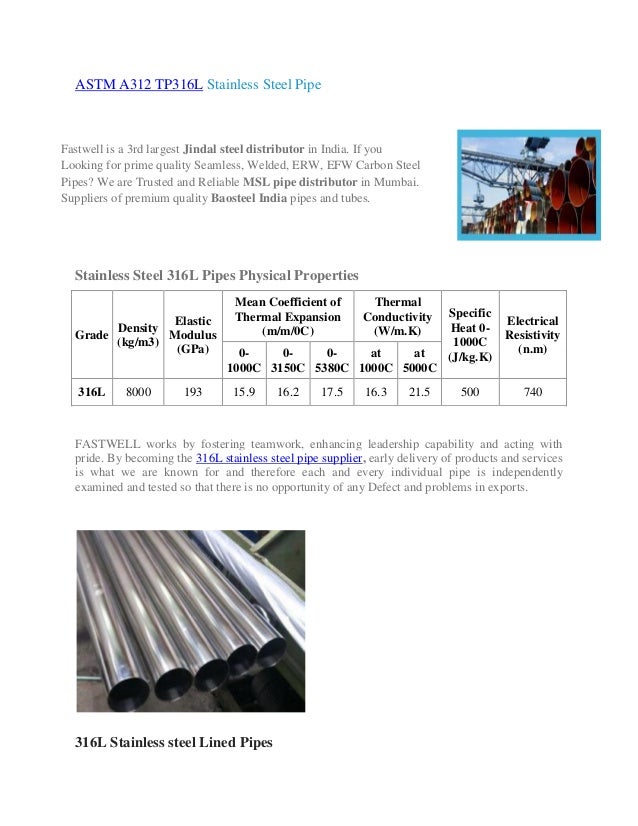

316l stainless steel data sheet. Ati 316l austenitic stainless steel uns s31603 product documents documents data sheet english pdf tolerance guide sheet pdf tolerance guide. These alloys also offer higher creep stress to rupture and tensile strength at elevated temperature. Since 316l stainless steel features better carbide precipitation resistance than 316 stainless steel 316l can be continuously exposed to the temperature of 427 c 857 c 800 f 1575 f where 316 is not advisable to. This data sheet applies to stainless steel 316l 1 4404 hot and cold rolled sheets plates and strip semi finished products rods rolled wire and profiles as well as seamless and welded tubes for pressure purposes.

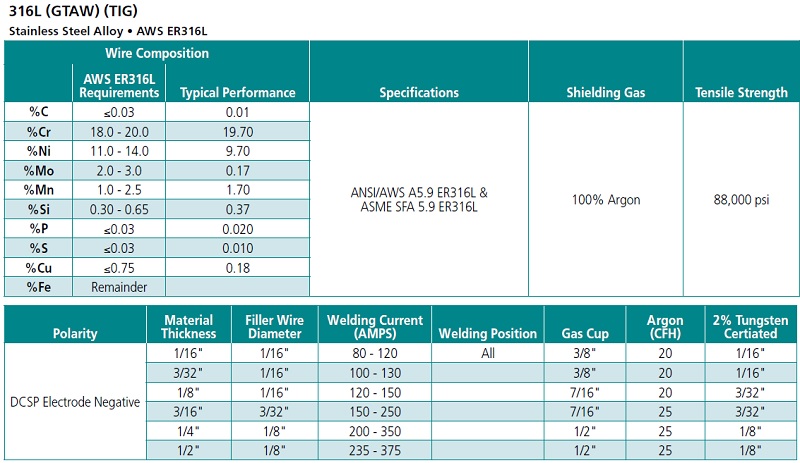

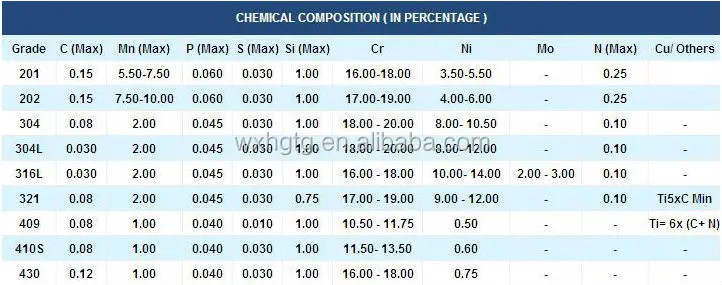

Alloy 316 316l applicationsalloy 316 316l uns s31600 s31603 is a chromium nickel molybdenum austenitic stainless steel developed to provide improved corrosion resistance to alloy 304 304l in moderately corrosive environments. Additional information available at our web site. 304 stainless steel sheet plate stainless steel sheet and plate 304 is the ideal choice due to its tensile strength high resistance to rust and high fabrication ability. 316l stainless steel is an extra low carbon version of 316 ss and while both grades are very similar 316 l is ideal for welding applications as it is less susceptible to weld decay.

Ati 316 ati 316l ati 317 and ati 317l alloys are molybdenum bearing austenitic stainless steels which are more resistant to general corrosion and pitting crevice corrosion. The low carbon content decreases carbide precipitation that sensitizes the grain boundaries of welds in these materials. Cost effective and versatile material 304 sheet is suitable for most applications where durable support and corrosion resistance are required. Though 316l features better corrosion resistance than 316 but its mechanical properties are not as good as 316.

316 316l stainless steel product description type 316l is an extra low carbon variation of type 316 that eliminates harmful carbide precipitation due to welding. Manganese mn 2 00 max. Types 316 and 316l are molybdenum bearing austenitic stainless steel which are more resistant to general corrosion and pitting crevice corrosion than the conventional chromium nickel austenitic stainless steel such as type 304.