410 Stainless Steel Sheet Uk

You ve been inactive for a while.

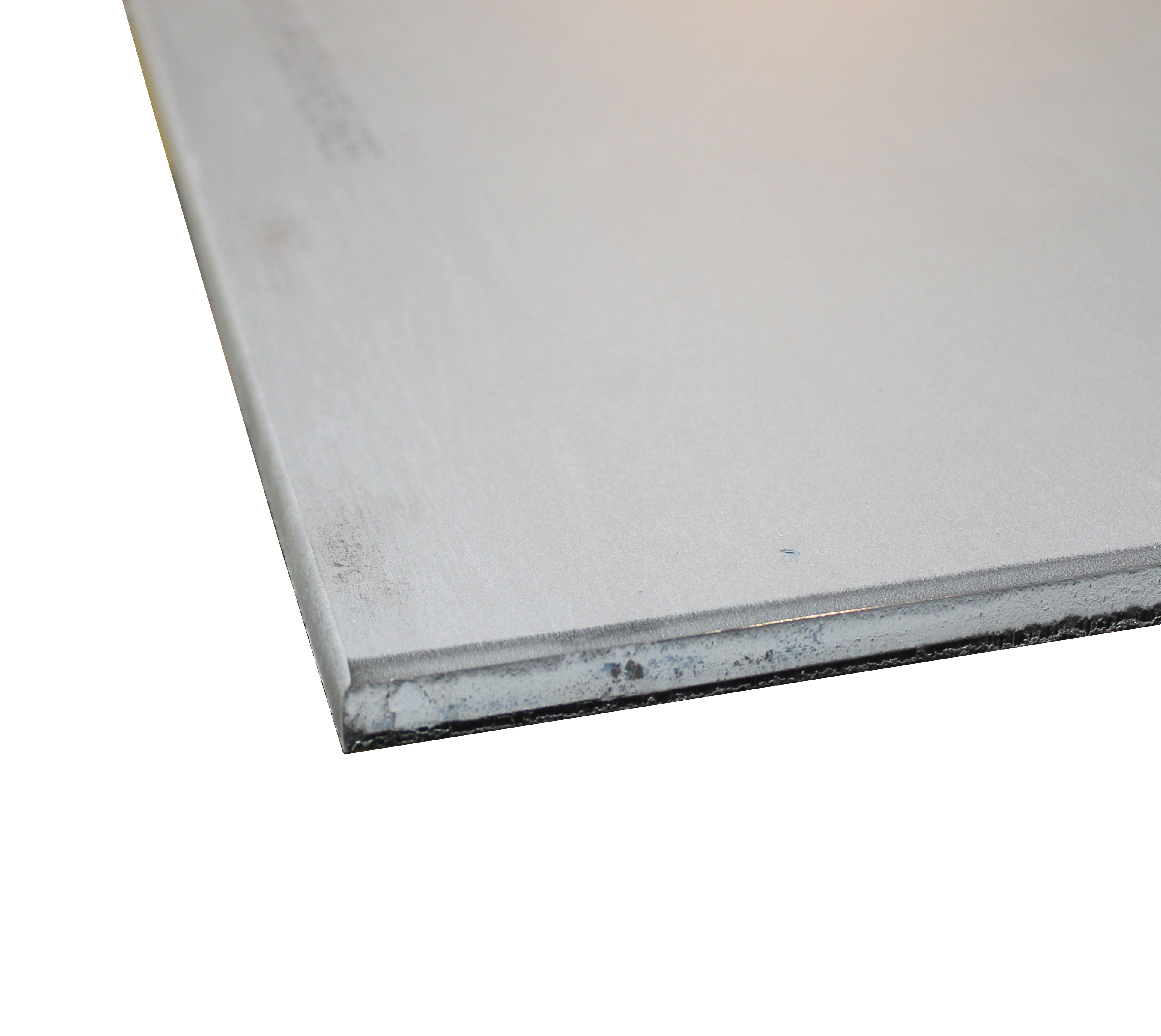

410 stainless steel sheet uk. The alloy contains 11 5 chromium which provides good resistance to atmospheric corrosion. Heat treated 410 has mechanical properties comparable to the engineering alloy steel aisi 4130 coupled with the additional benefit of good corrosion resistance. 410 stainless steel is the basic martensitic stainless which will attain high mechanical properties after heat treatment. Type 410 stainless is a martensitic alloy commonly supplied in the hardened but still machinable condition.

It maintains its corrosion resistance in temperatures up to 1200 f. 410 alloy is required when strength hardness and wear resistance is required with some corrosion resistance. Often used for fasteners and valves 410 stainless steel withstands wear caused by abrasion. Precision ground on the top and bottom to a tight tolerance these sheets and bars are also known as flat stock.

Stainless steel manufacturers distributors 303 304 316 316l 410 416 431 f51 f55 174ph standard grades imco special grades sheffield uk. 410 410 stainless is a corrosion and heat resistant 12 chromium steel. If you desire a steel that has moderate corrosion resistance and high mechanical properties 410 is the ideal grade to select. Or you can click log off now if you are done.

Type 410 stainless steel 410 stainless steel is a hardenable martensitic stainless steel alloy. It is the most widely used of the hardenable stainless steels. 410 stainless datasheet type 410 is hardenable straight chromium stainless steels which combine superior wear resistance of high carbon alloys with the excellent corrosion resistance of chromium stainless steels. 410 is highly resistant to atmospheric corrosion.

It has good impact strength corrosion and scaling resistance up to 649 c. For your security we will automatically log you off in approximately one minute unless you click stay online to continue. However corrosion resistance is limited unless the alloy is further enhanced by processes including hardening tempering and polishing. It is magnetic in both the annealed and hardened conditions.

A wide range of properties can be developed with different heat treatments.