Advantages Of Sheet Metal Bending Process

Although the standard bearer for sheet metal bending is the press brake sheet metal folding machines have proved to be an invaluable companion for any fabrication shop or manufacturing company.

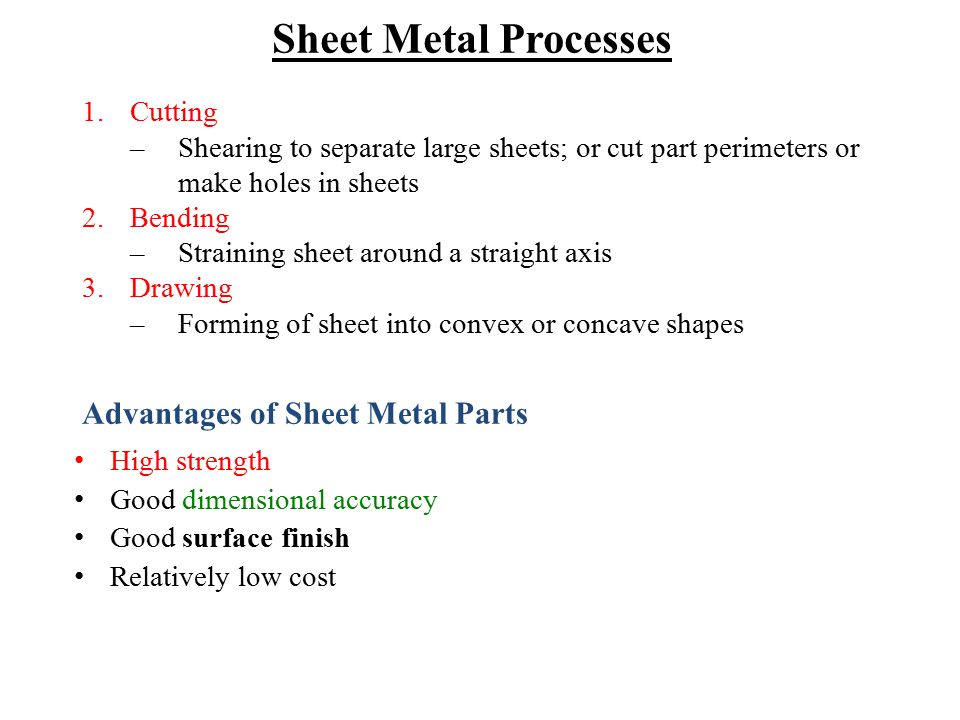

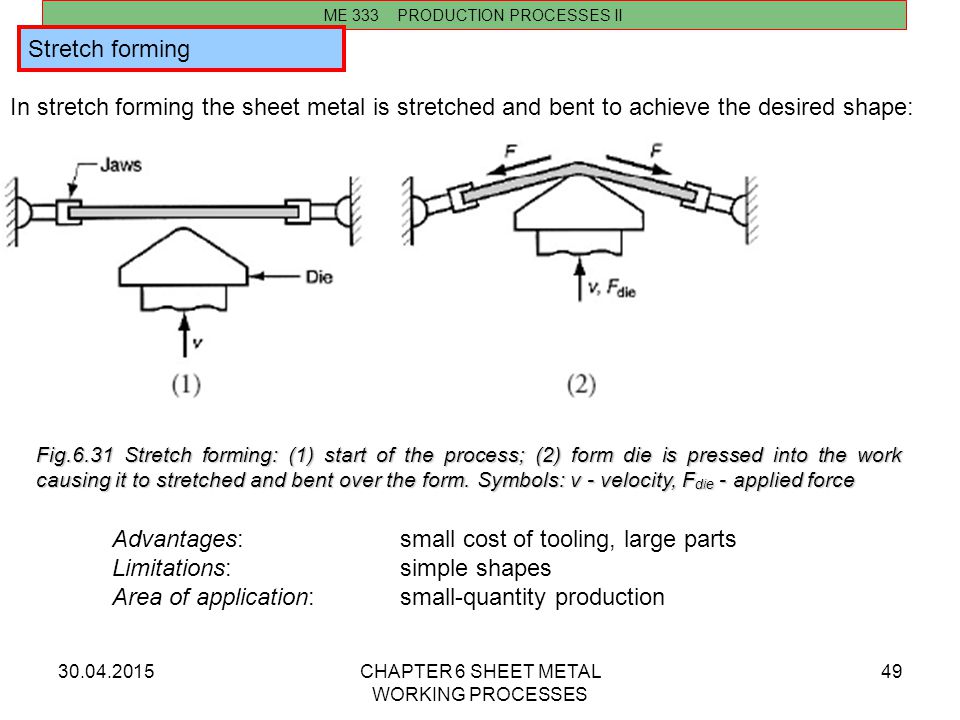

Advantages of sheet metal bending process. The advantages and disadvantages of metal fabrication. With the different types of weather conditions this sheet metal fabrication seems to work perfect. Roll forming this process is for long parts with constant complex cross sections. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.

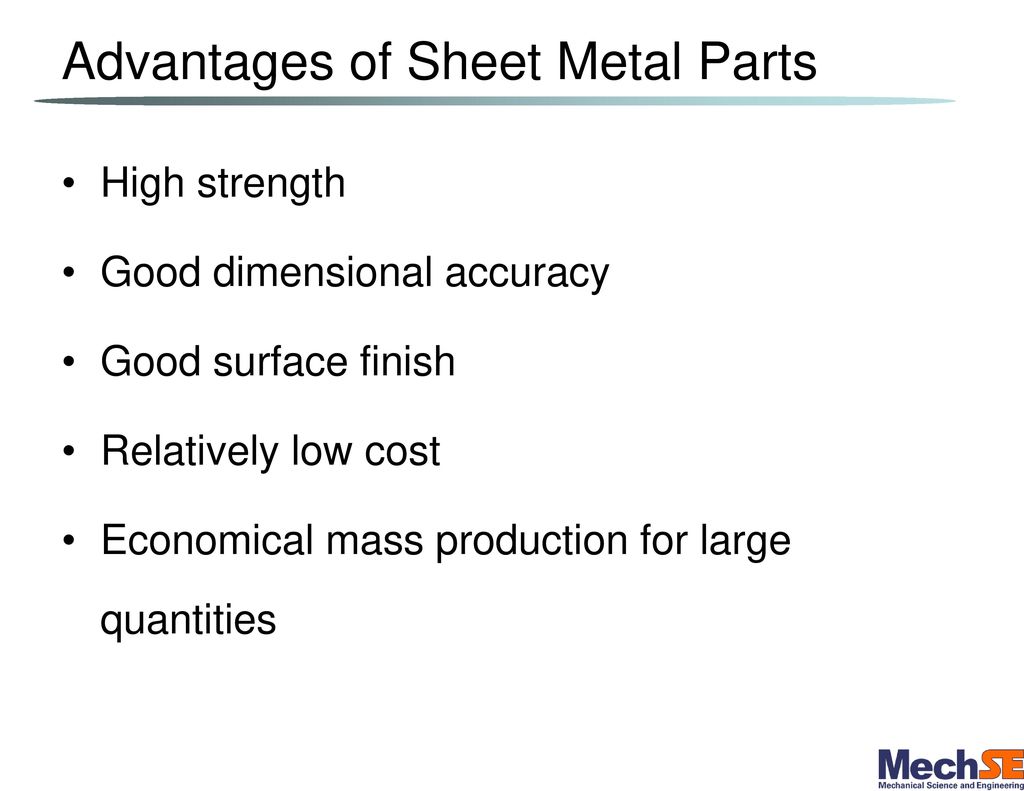

Thinness and low in weight can be transported easily. There are various processes to transform sheets into required product. Sheet metal bending is the plastic. Are sheet metal products.

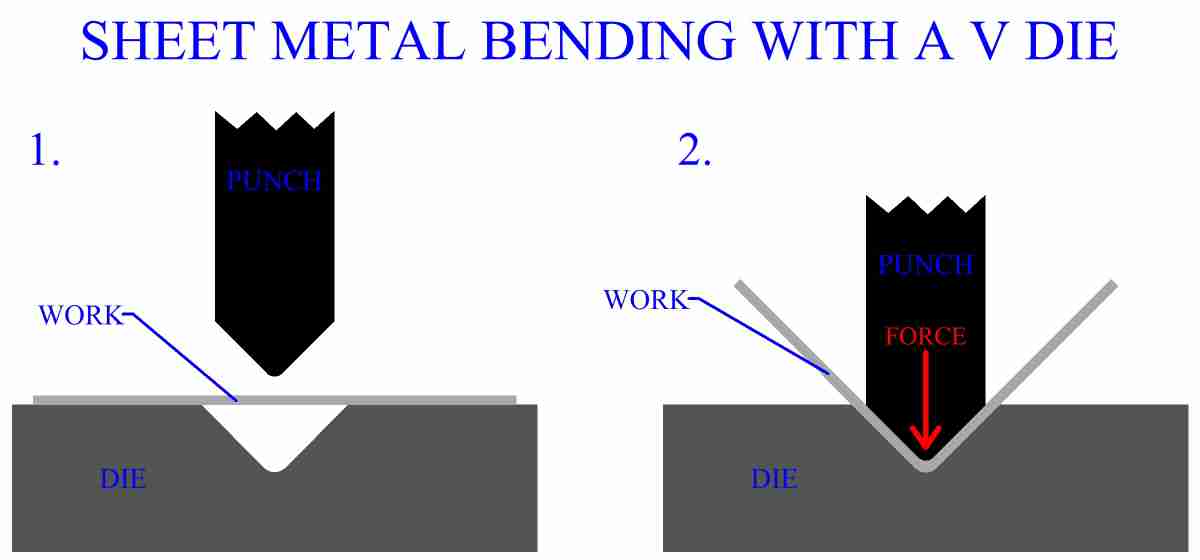

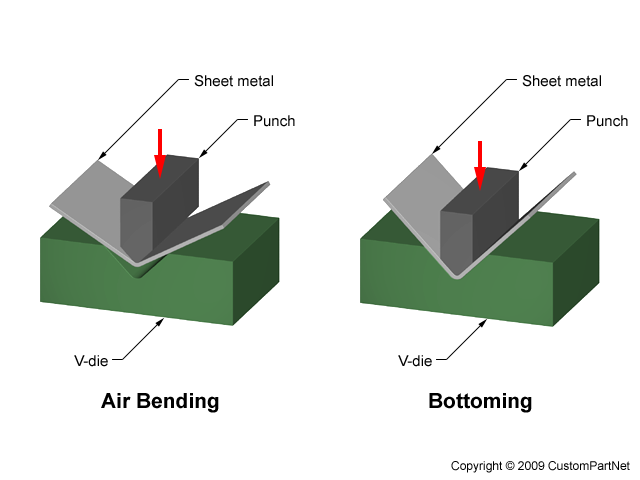

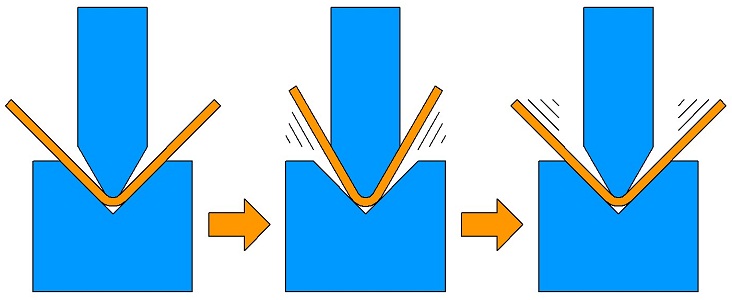

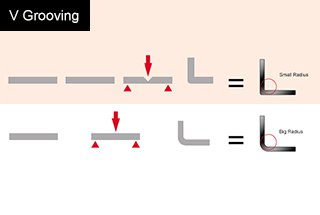

Bending metalworking air bending edit this bending method forms material by pressing a punch also called the upper or top die into the material forcing it into. Due to its various advantages sheet metals are widely used in manufacturing industries. Even if the temperature rises a bit metal does not easily degrade. Air bending air bending is the most common type of bending process used in sheet metal in this process the work piece is only in contact with the edge of the die and the tip of the punch the benefits of air bending are as following.

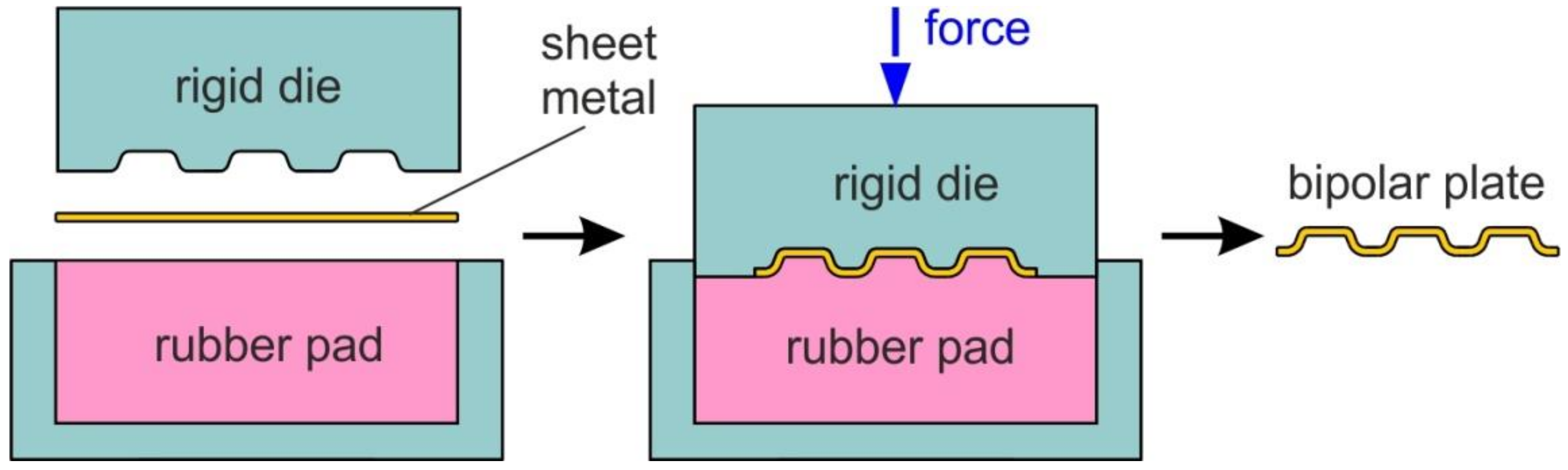

This list compares the good and bad of each process so you can determine the proper one for your own unique requirement. Resistance to sun corrosion and also moisture. Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more. Work piece material size and.

Sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions. Metal is harder and stronger than plastic. Bending processes differ in the methods they use to plastically deform the sheet or plate. All cars bodies metal doors fan blades metal desks etc.

Relationship of a high strength. Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more. Bottoming edit coining edit three point bending edit folding edit. Higher versatility with less tooling.

With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces. Sheet metal processes are versatile processes used in metal forming industries. Bending of sheet metal is a common and vital process in manufacturing industry.