Adjust Bend Radius Sheet Metal Brake

Remove them from the brake and stack one inside the other.

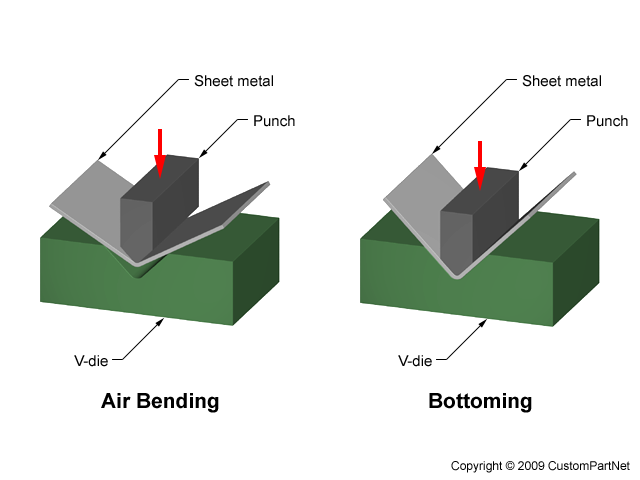

Adjust bend radius sheet metal brake. Blue 6 foot or 8 foot models with radius tube radii tubes and radii heads. Choose a bend radius that matches your minimum bend. The tubing will become the fulcrum around which the sheet metal is bent. If one test strip is over bent or has a sharper radius move the end of the clamp which that strip came from back slightly.

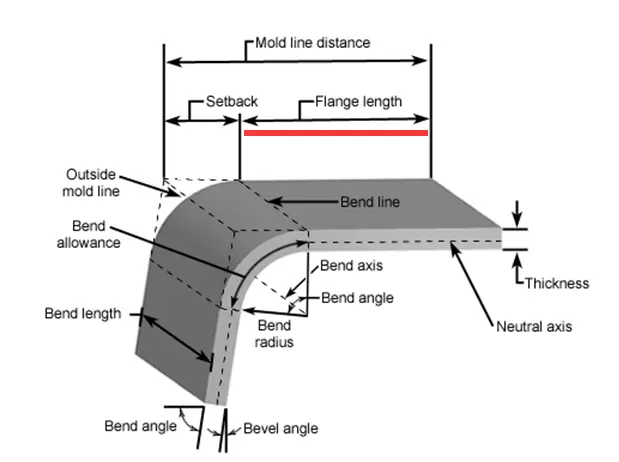

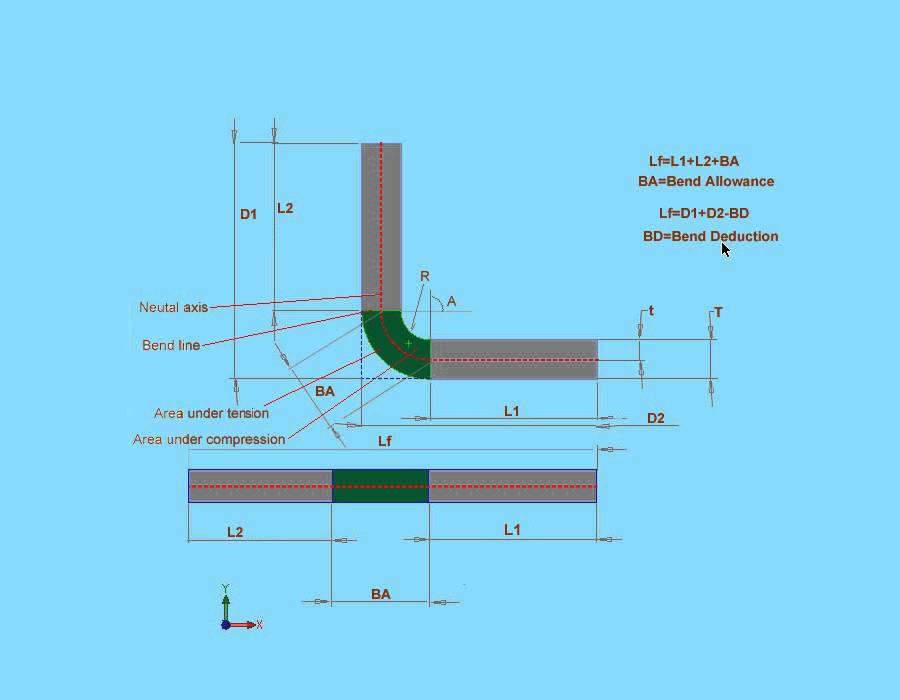

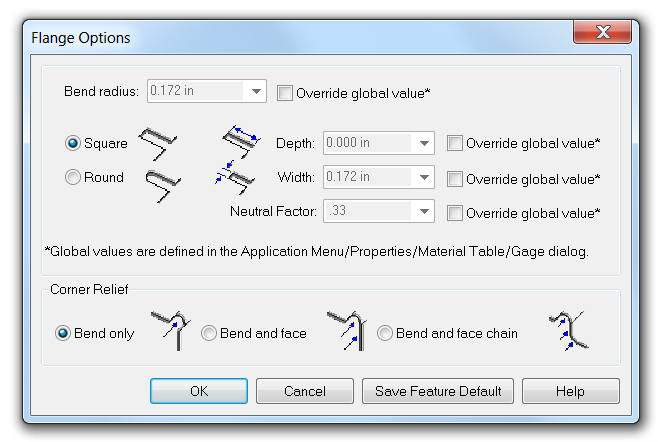

Set clamping pressure to zero or almost none and radius set back to at least 1 5 times material thickness when forming 18ga and 2 3 times for 16ga or heavier. The brake must be adjusted so that the fingers are set back from the edge by an amount equal to the radius of the tube plus the thickness of the material you are bending. Height of arc 2 material thickness 2 inside radius 0 201 2 0 01562 inside bend radius 0 201 0 031 0 170 in. Additionally the clamp height has to be adjusted for the combined thickness of the sheet and the bar.

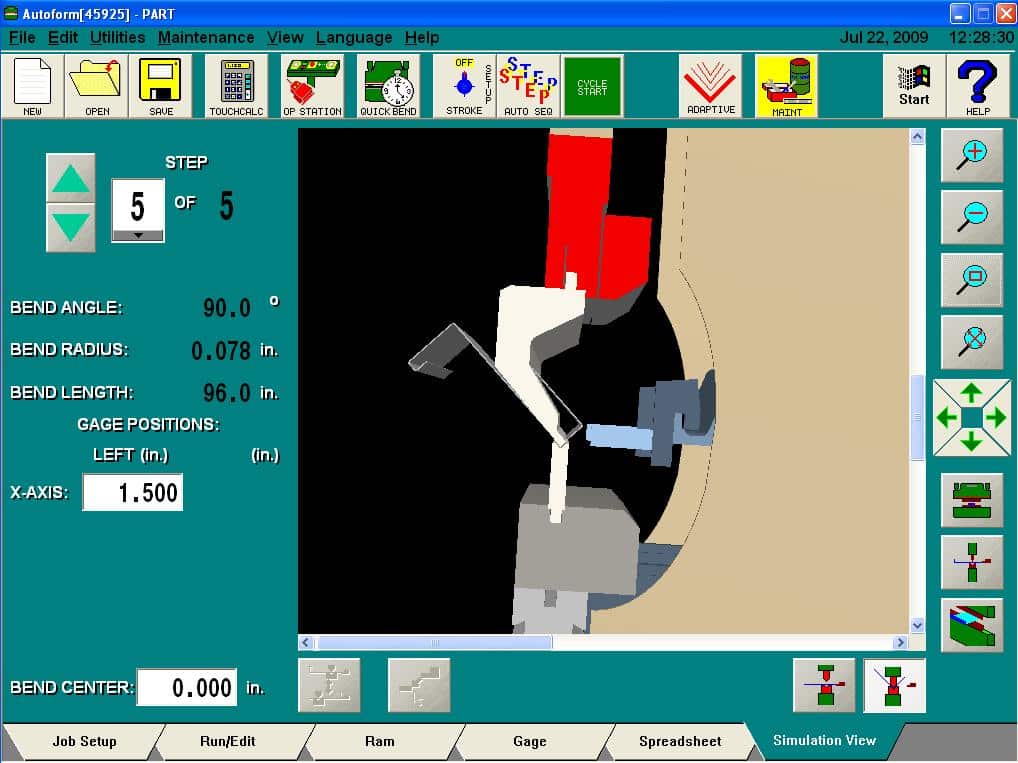

That s why it is important to understand the material s capabilities and what you should avoid designing around a bend so you can avoid common press brake design mistakes before the design goes into production. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows. This is my bending brake i made it from 4mm thick 40 x 40mm l profile6 and 12mm steel bars and 3 4 and 6 mm thick flat bars i wanted to get brake that could bend 2 3mm thick steel. Bend to about 90 degrees and see if they appear to be bent to the same degree.

Now we take the height of arc value for our new bend angle and we plug it into the following formula. Metal bending brake radius brake or radius brakes on floor stands from mittler bros. Sheet metal bending brake with radius adjustment. It is also possible to bend and flatten a hem to form a radius and to bend a zig zag.

Determine your minimum bend by measuring the distance from your closest feature i e. A cutout or the edge of your flange to your bend. The decisions you make about the bend radius during the design stage will determine how difficult it will be to produce the design. At least adjust your brake for the heaviest material you use and leave it there for the lighter material too.

Metal bending radius brakes javascript seems to be disabled in your browser. We also explain how to make a sheet metal box or pan. Compare the sharpness of the radius. Height of arc outside bend radius.

Insert sheet metal under clamping bar. Also i wanted to be able to do some bends with bigger radius witho.