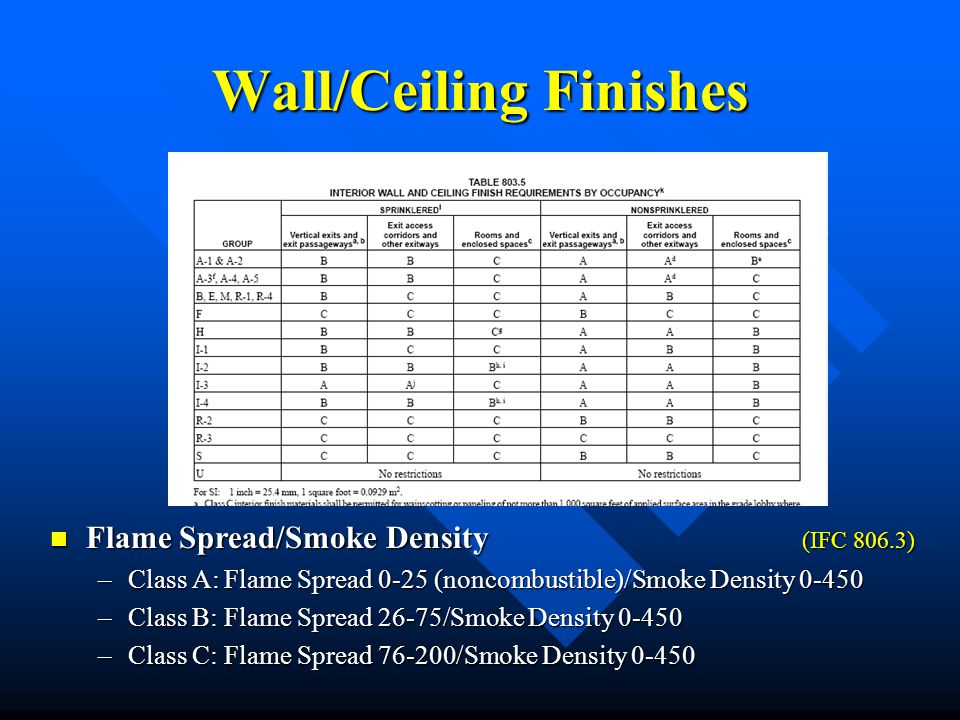

Acrylic Sheets With Class B Flame Spread

To achieve a class 0 fire rating products must meet specific british standards and pass a series of tests designed to test flame spread and propagation.

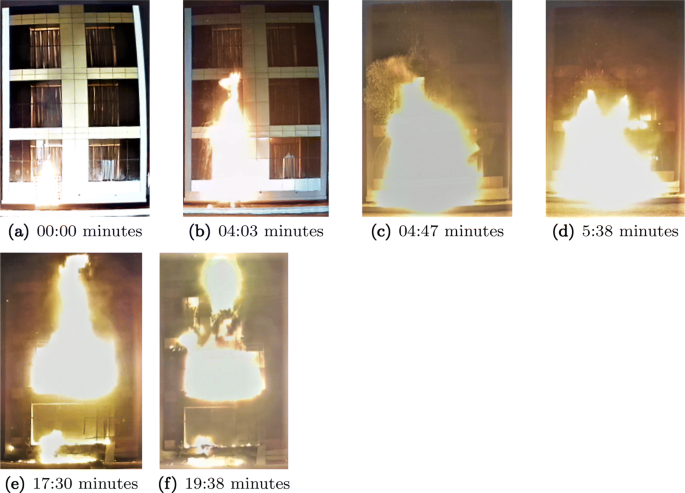

Acrylic sheets with class b flame spread. Acriglas sheet is a combustible thermoplastic and is classified as a slow burning plastic. For example if the flame travels 19 1 2 feet in less than 5 1 2 minutes the time required for flame to spread on 19 1 2 feet of red oak the rating is 100 times 5 1 2 divided by the time minutes in which flame spreads 19 1 2 feet on the sample. Overview of ul 94 flame classifications. Optix acrylic sheet is a lightweight impact resistant optix acrylic sheet is a lightweight impact resistant transparent material that is a great replacement for glass in many applications.

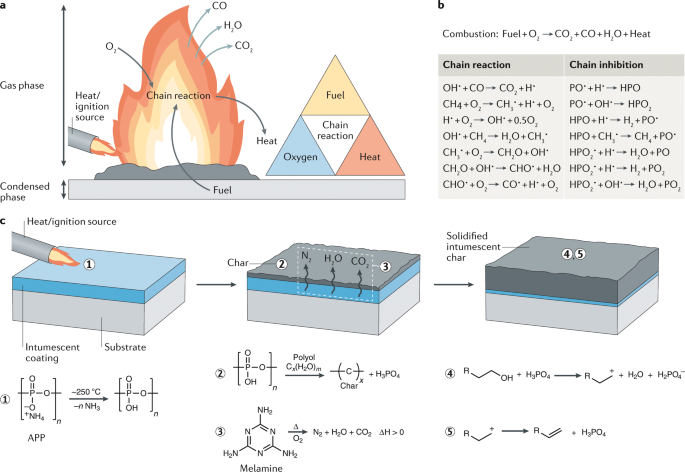

The first determines the material s tendency either to extinguish or to spread the flame once the specimen has been ignited. Flame retardant polycarbonate sheets. Acrylic flammability data flammability. Access panels may be required for evacuation and venting of rooms glazed with acriglas sheet.

Is an authorized stocking distributor of lexan polycarbonate sheet products including flame retardant lexan 9034v. Plexiglas m g t or q acrylic sheet. Precautions should be taken to protect the material from flames and high heat sources. The product must first meet the fire propagation requirements as outlined in bs 476 6 1989 a1 2009.

Although stronger than glass and plexiglass fire rated polycarbonate is easily die cut punched and sheared to meet your fabrication. Lexan thermoclear thermoclick and corrugated sheet products have a class a classification. A product must be also be classified as a class 1 building material for bs 476 7 1997. Ac plastics is proud to offer makrolon low flammability lf plastic sheeting solutions.

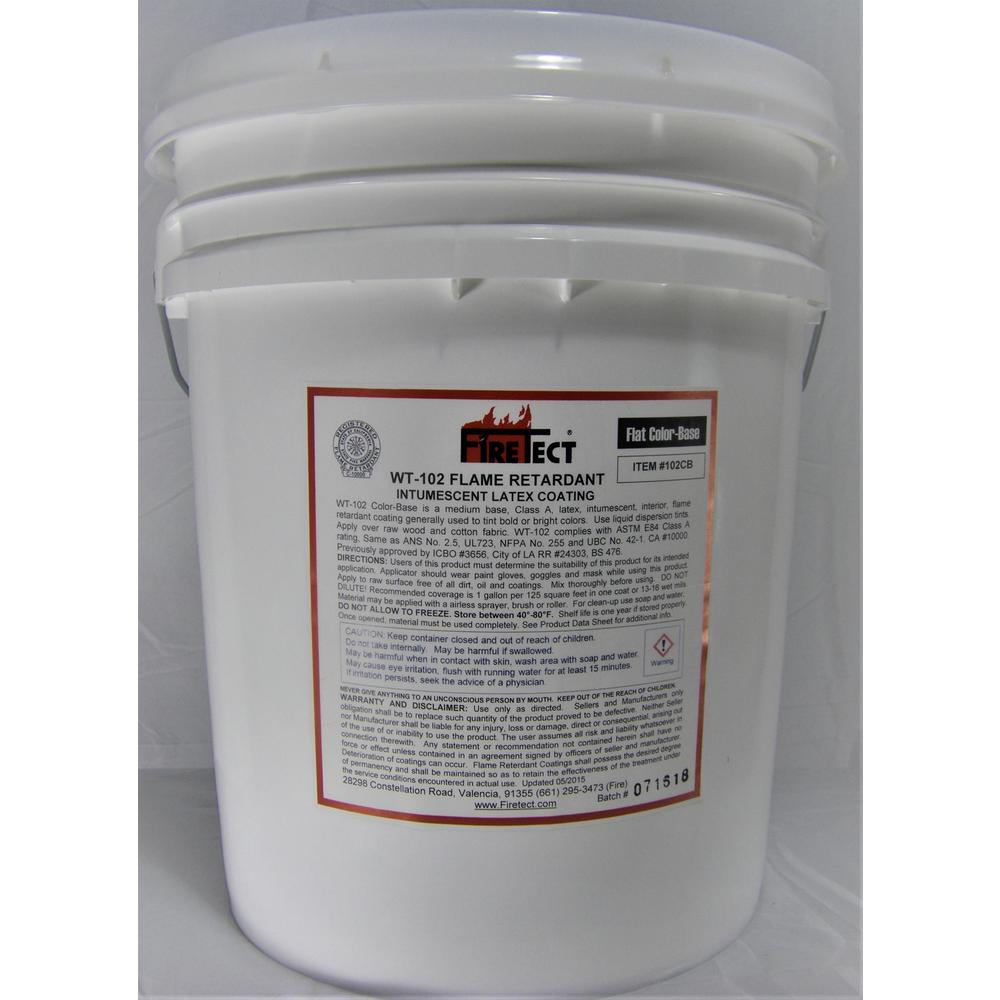

Fire rated polycarbonate sheet is a flame inhibiting uv stable plastic sheeting and glazing product that is virtually unbreakable. Ul 94 the standard for safety of flammability of plastic materials for parts in devices and appliances testing there are two types of pre selection test programs conducted on plastic materials to measure flammability characteristics. Its higher impact strength makes it a great glass replacement for applications such as garage door windows storm windows and other glazing needs. When paints are applied to substrate materials that have been tested and classified interior paints and coatings have been found to have no effect on the flame spread index or smoke density index of rated materials.

We do not use lead cadmium mercury or chromium in our process to manufacture these plexiglas products nor is it used as an additive for these products. From these observations a flame spread rating can be calculated. The ul listed material for flammability is a clear polycarbonate sheet that combines excellent formability and impact resistance. Altuglas international has no reason to suspect any traces of lead cadmium mercury or chromium are contained within the following plexiglas clear products.