Acrylic Sheet Thermal Conductivity

For amorphous plastics at 0 200 c the thermal conductivity lies between 0 125 0 2 wm 1 k 1.

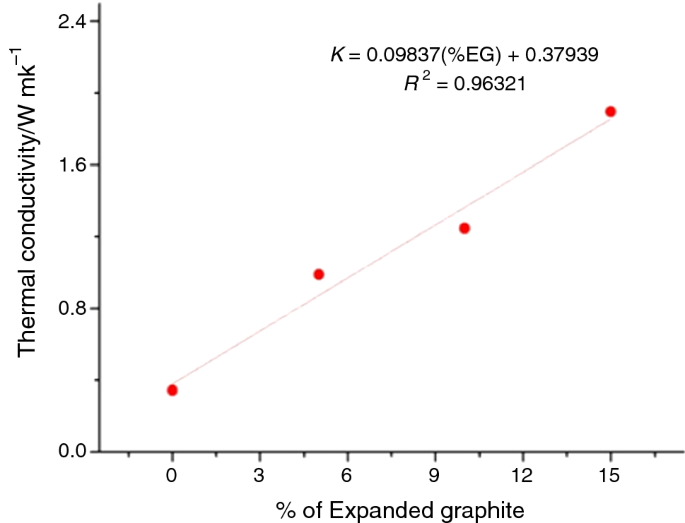

Acrylic sheet thermal conductivity. 3m thermally conductive acrylic interface pad 5571n and 5571dl consist of a highly conformable slightly tacky acrylic elastomeric sheet filled with conductive ceramic particles which provides special features listed as follows. With higher thermal conductivity 3 0w m k and low hardness asker c 5 3m pad 5550h consists of a highly conformable. 10 5 0 07 14 k mm m din 53752 a. Material thermal conductivity w m 1 k 1 temperature k electrical conductivity 293 k ω 1 m 1 notes acrylic glass plexiglas v045i.

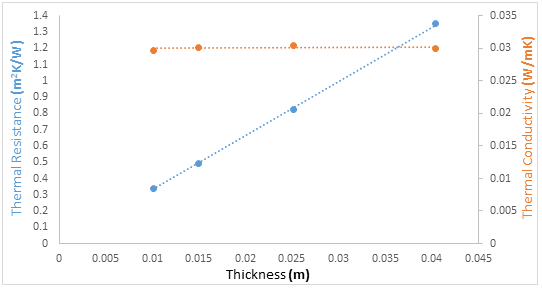

Acrylics offer high light transmittance with a refractive index of 1 49 and can be easily heat formed without loss of optical clarity. Plexiglas acrylic sheet will expand and contract with changes in temperature and humidity different temperature and or humidity conditions on the inner and outer surfaces of plexiglas sheet may cause it to bow slightly in the direction of the higher temperature and or humidity however this type of bowing is reversible the sheet will return to its original flat state when the temperature and humidity differentials become zero. There are no negative conductivities and the symbols that could be read that way are hyphens to separate various estimates and measurements. W mk u value for thickness 1mm 3mm 5mm 10mm.

Thermal conductivity w m k 1 upper working temperature c polyimide pi 30 60 360 270 1090 0 10 0 35 23c 250 320 polymethylmethacrylate pmma acrylic 70 77 105 95 40 1400 1500 0 17 0 19 23c 50 to 90 polymethylpentene tpx 117 100 40 20 to 40 2000 0 17 23c 75 115. Coefficent of linear thermal expansion a for 0. Prolonged exposure to moisture or even total immersion in water does not significantly effect the mechanical or optical properties of acrylic. The thermal insulating capacity of plastics is rated by measuring the thermal conductivity.

Thermal conduction is the transfer of heat from one part of a body to another with which it is in contact. K thermal conductivity w mk btu hr ft f dt t 1 t 2 temperature difference o c o f s wall thickness m ft conductive heat transfer calculator. Thermal properties astm test method units values maximum recommended continuous service temperature f 170 190 softening temperature f 210 220 melting temperature f 300 315 deflection temperature 264 psi 66 psi d 648 f 203 207 coefficient of thermal expansion 30 to 30 c d 696 in in f x 10 5 3 0 thermal conductivity c 177 btu ft hr ft2 f 0 075. K thermal conductivity w mk btu hr ft f s wall thickness m ft a surface area m 2 ft 2 dt t 1 t 2 temperature difference o c o f.

Possible expansion due to heat and moisture.