Acetal Resin Sheet Glued To Acrylic

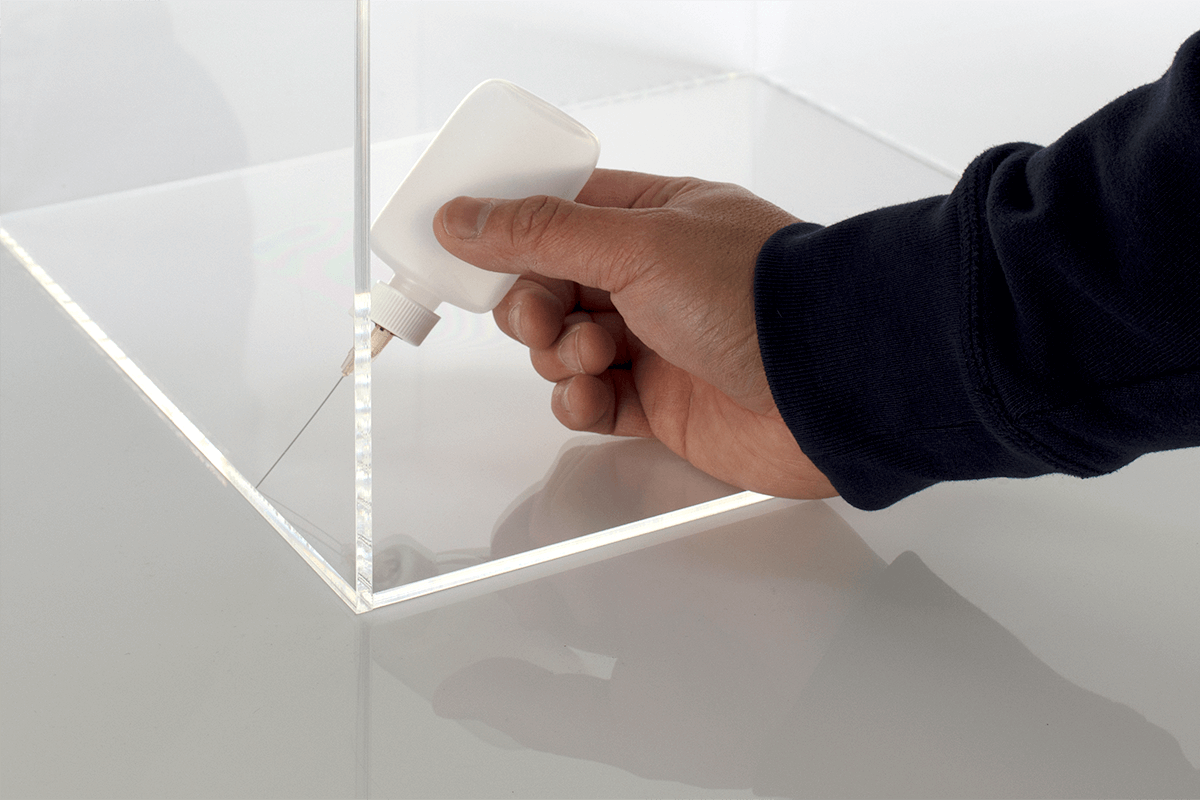

Once the acrylic has been glued hold it together for about 15 to 30 minutes.

Acetal resin sheet glued to acrylic. Acetal polyoxymethylene is a strong and rigid thermoplastic that has good moisture heat and chemical resistance. This plastic is fairly low cost and has good structural properties it is often used instead of metal. Looking to glue acetal plastic. Acetal is a popular thermoplastic its use spans a number of industries.

Soon after applying you ll notice the acrylic s joined edges are cloudy white. Another option is 2 part polyurethanes. It is commonly used in industries as a replacement for metals due to its lightweight low cost and good structural properties. The two basic types of acetal resins are acetal copolymer celcon and acetal homopolymer delrin.

To bond acetal cure the es5748 at the low temperature end of the cure schedule. Bonding acetal for maximum strength. Once 15 to 30 minutes have elapsed you can stop holding the acrylic together a light bond has already been formed. Due to the high temperature resistance of acetal epoxies such as permabond es5748 can be considered.

Acetal which is chemically known as polyoxymethylene pom is a semi crystalline copolymer plastic. Bonding acetal with adhesive. First developed in the mid 1950 s acetal plastic is extremely stiff and dimensionally stable. As it dries it will slowly become more transparent.

Delrin is an acetal homopolymer polyoxymethylene acronym pom resin manufactured by dupont engineered plastics which is also manufactured by ticona as an acetal copolymer under the trade names of hosaform duracon and celcon by basf as ultraform by quadrant epp as acetron.