Ac Pulsed Gmaw Improves Sheet Metal Joining

3 a pulse cycle is defined as a period from the beginning of a pulse to the end of the base time just before the next pulse.

Ac pulsed gmaw improves sheet metal joining. Sometimes welding suppliers and welding managers don t want to try it because they don t want to change the process they re using train users adjust welding processes or spend money on new equipment while any pulse spray machine can perform short circuit transfer each type of transfer has distinct differences and. It uses a high voltage and current which results in the molten metal from the electrode being vaporized into a steam. Some pulsed gmaw power sources allow welding operators to adjust the width of the arc cone which helps them tailor the bead profile to the application. Ac aluminum pulse gmaw brings features that cannot be realized with standard dc pulse mig welding.

This eliminates spatter and creates a high quality weld finish. A digital inverter controlled ac pulsed gmaw system has been developed for welding sheet metal structures. Historically if gmaw were to weld heat sensitive metal at all conventional dip arc or short circuiting gmaw was the best option. Pulsed gmaw is a good solution for welding this material and avoiding such pitfalls.

Pulsed gas metal arc welding gmaw p is a variation on the spray transfer mode of the process. Gas metal arc welding gmaw process developments have perfected the technology so it can weld extremely thin material see figure 1. Ueyama t tong h harada s ushio m 2000 improve sheet metal welding quality and productivity with ac pulsed mig welding system. Prevent over welding and poor fusion.

A microcomputer controlled inverter type ac pulsed gma welding. When joints are located out of position and difficult to reach pulse welding can produce cleaner welds. Pulse spray gas metal arc welding gmaw is a versatile welding process. The base metal can congeal to the weld puddle during the trough in current preventing it from dripping out of the joint.

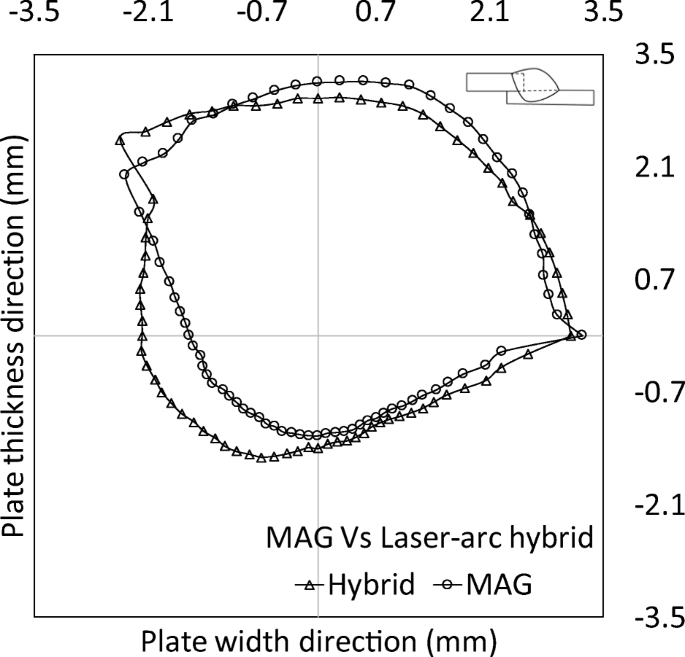

Welding arcs with both polarities en and ep were obtained using a high speed video camera operating at 2250 frames per seconds. 12 13 thin metals. Productivity increases with improved deposition rates using ac aluminum pulse gmaw waveform technology are. The innovative use of gas metal arc welding gmaw in improvement of quality and productivity of sheet metal joints was described.

The arc is quite stable by extracting arc length related voltage through the intelligent filter. Pulse welding on thin metals reduces the risk of burn through.