Abs Plastic Sheet Forming Temperature

This chilling may be 50 to 100 f on the areas that touch the mold on the mold surface side in just a matter of seconds.

Abs plastic sheet forming temperature. This makes the plastic considerably harder in these areas and when you apply the vacuum to stretch the. Its glass transition temperature is approximately 105 c 221 f. If it doesn t reach forming temperature crank it up another 10 and give it more time check again. It has very high impact strength and stiffness excellent high and low temperature performance and outstanding formability.

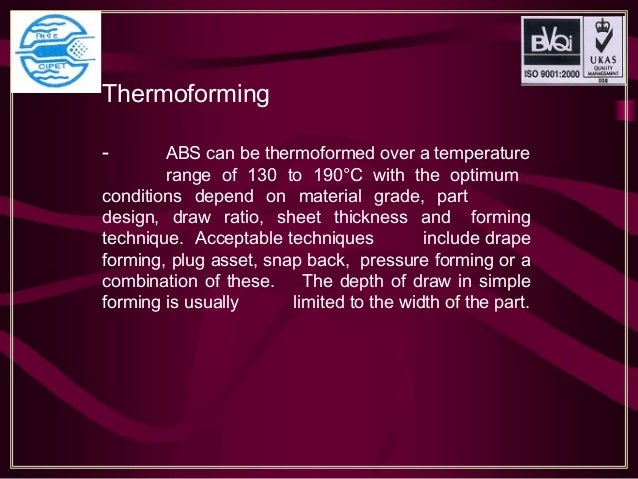

Wait about 10 minutes for it to warm fully. Place the plastic sheet on a cookie sheet and place in an oven set to 250 f. Royalite r20 thermoplastic sheet is a rigid abs product with a combination of properties that makes it ideal for the widest range of applications. Abs is easily thermoformed and lends itself to remarkable reproduction of mold detail.

Set the oven to around 230 and give the abs some time in there. The maximum working temp is 185 deg f and the forming temperature is 325 350 deg f. Sheet surface temperature will directly correspond to material gage. Thermoplastic as opposed to thermoset refers to the way the material responds to heat.

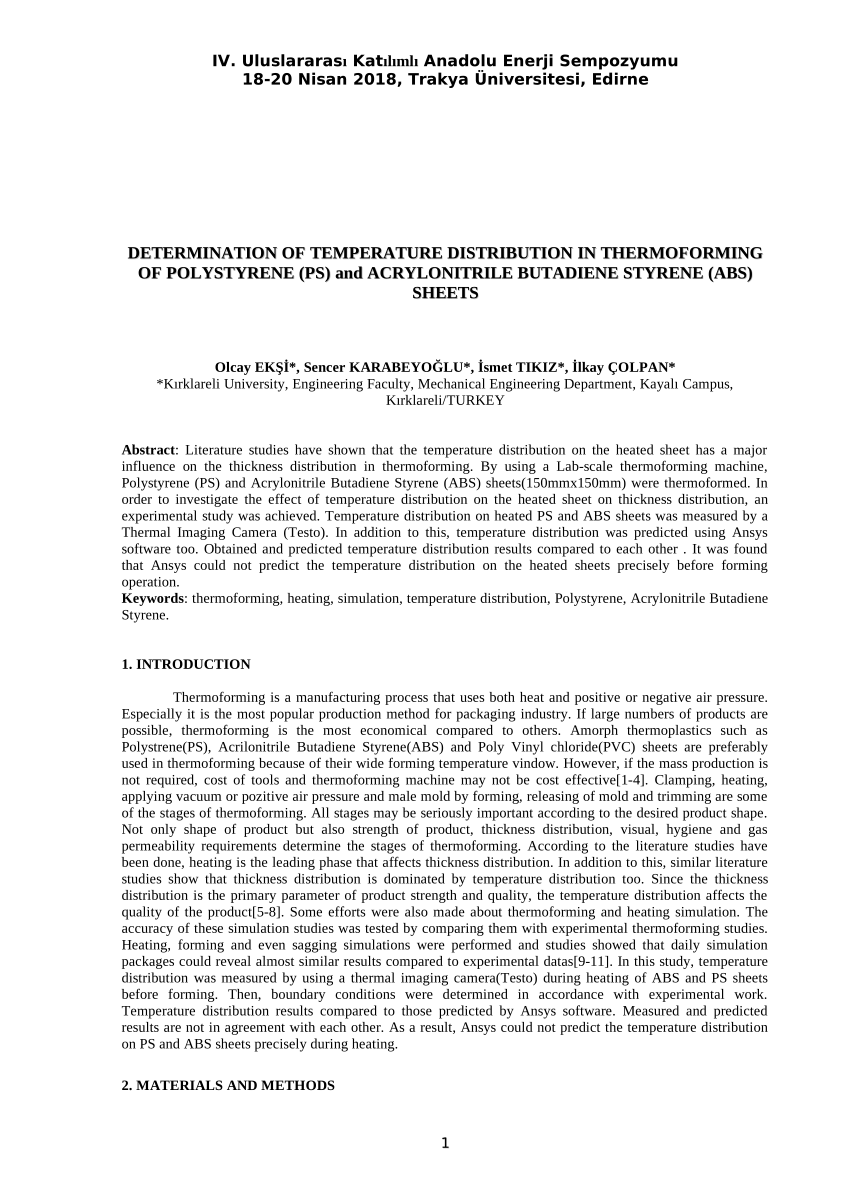

High density polyethylene hdpe which requires a core temperature of approximately 280 f for optimal forming. Acrylonitrile butadiene styrene abs is an opaque thermoplastic and amorphous polymer. Black is uv resistant while white and natural colors are not. 7 put on your gloves when you work with the plastic.

To achieve this core temperature the former must calculate the temperature differential on both sheet surfaces. When it s ready you ll find it flexible when you try to pick it up. Have a glass transition at a certain temperature 221 degrees fahrenheit in the case of abs plastic. Tg s for polystyrene and acrylic are around 210 f 100 c.

Extruded abs sheet can be easily heat formed using any conventional thermoplastic sheet forming equipment. The template failed verification is being considered for merging abs is amorphous and therefore has no true melting point. Thermoplastics become liquid i e. The glass transition temperature for nylon 6 is only 122 f 50 c.

Polycarbonate has a glass transition temperature of about 147 c 297 f so it softens gradually above this point and flows above about 155 c 311 f. Abs properties and material options. Tools must be held at high temperatures generally above 80 c 176 f to make strain and stress free products. The tg for polyethylene is around 125 f 90 c and that for homopolymer pp is 15 f 10 c.

Acrylonitrile butadiene styrene abs chemical formula c 8 h 8 x c 4 h 6 y c 3 h 3 n z is a common thermoplastic polymer. No big deal just take the time to bring it up to temp while checking on it. Plastic that touches the mold to cool very abruptly and freeze onto the mold surface wherever it actually touches the mold.