5052 Aluminum Sheet Bend Radius

Min 90 degree cold bend radius for 064 thick.

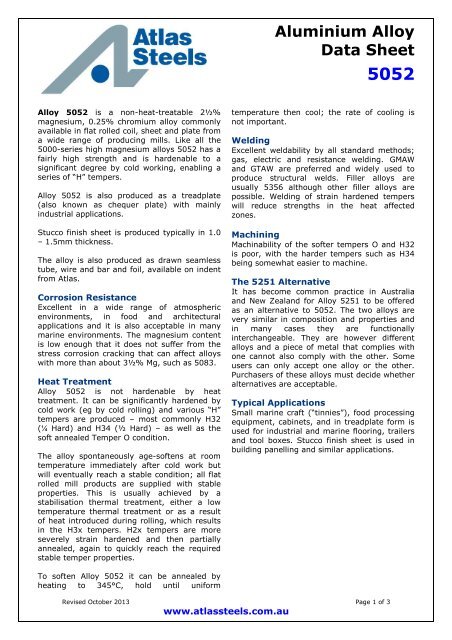

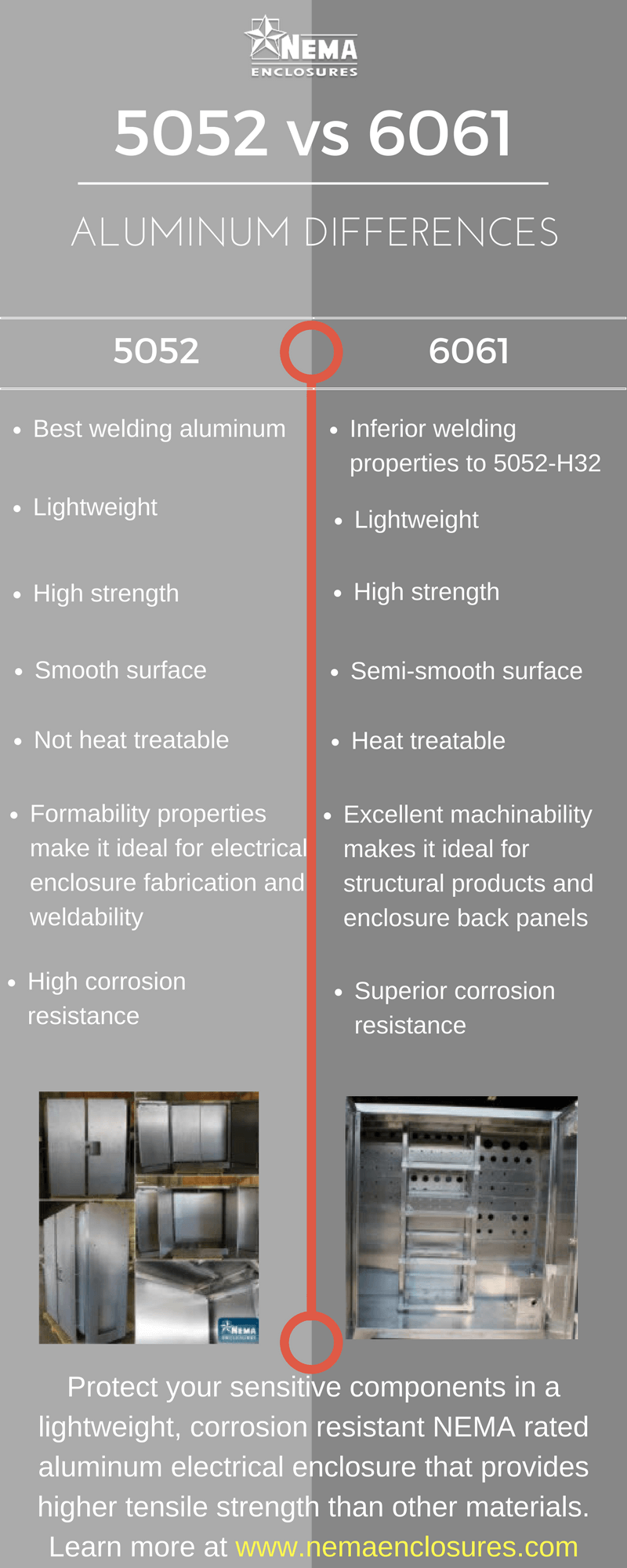

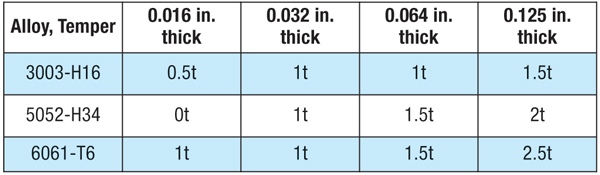

5052 aluminum sheet bend radius. 2024 t3 1020 1025 4130 ann. Radii for various thicknesses expressed in terms of thickness t. 5052 h32 conforms to astm bb209 qq a 250 8 ams 4015 ams 4016 ams 4017. We recommend 5052 h32 for aluminum chassis projects.

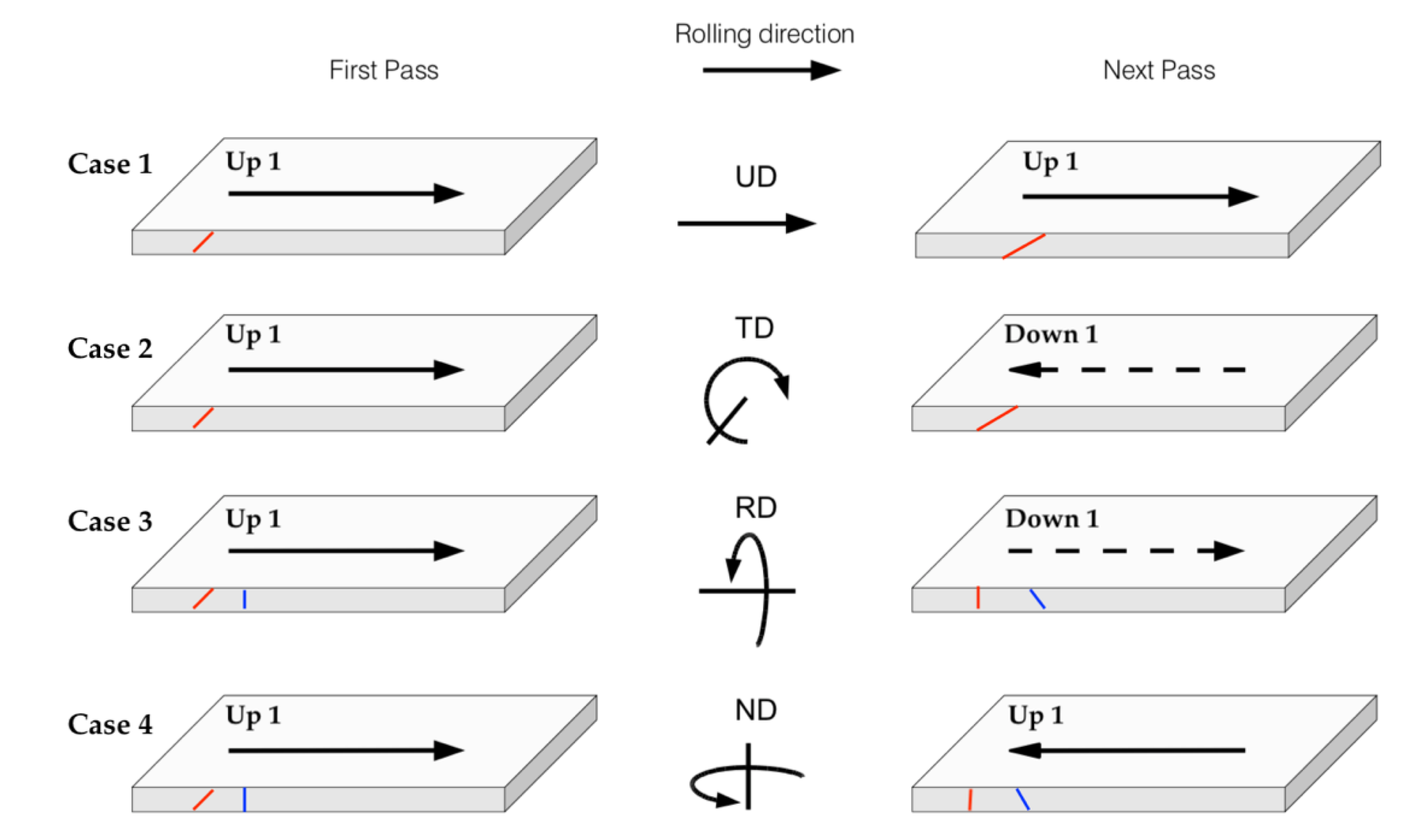

3003 0 1100 0 6061 s0 5052 s0. Recommended minimum bend radii for steel and aluminum. Another factor to consider is that during the process of bending the metal hardens and strengthens by reason of the working effect. The minimum bend radius data shown in these charts is measured to the inside of the bend.

In general parts should be designed with a minimum 1t bend radius radius matching the sheet thickness for the simplest setup and to ensure we can form the intended geometry. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. 1t the above values are average and may be considered as representative of 5052 h32.

Sheet metal bend radii if these guidelines are not followed more research and or some form of analysis may be requried. Per the aluminum association inc. Apart from alloy selection thickness and bend radius are also critical factors that must be considered. Specifing a bend radius from here will help prevent hair line cracks.

Factor 2 thickness and bend radius. If your bend radius needs to be adjusted a member of engineering design services team will contact you before your design is manufactured. Aluminum minimum bend radii for 90 degree cold forming of sheet and plate. O0 0 01 2t 1t 1t 11 2t 2 h320 0 1t 11 2t 11 2 2t 22t.

5052 h32 1 1 1 2 3 4 8 12 6061 t6 2 3 3 4 6 8 18 32 aluminum minimum bend radius in 1 32nds of an inch. 5052 h34 6061 t4 2024 0.