5052 Aluminum Data Sheet

Cut piece total 5052 aluminum sheet 5052 is alloyed with 2 5 magnesium.

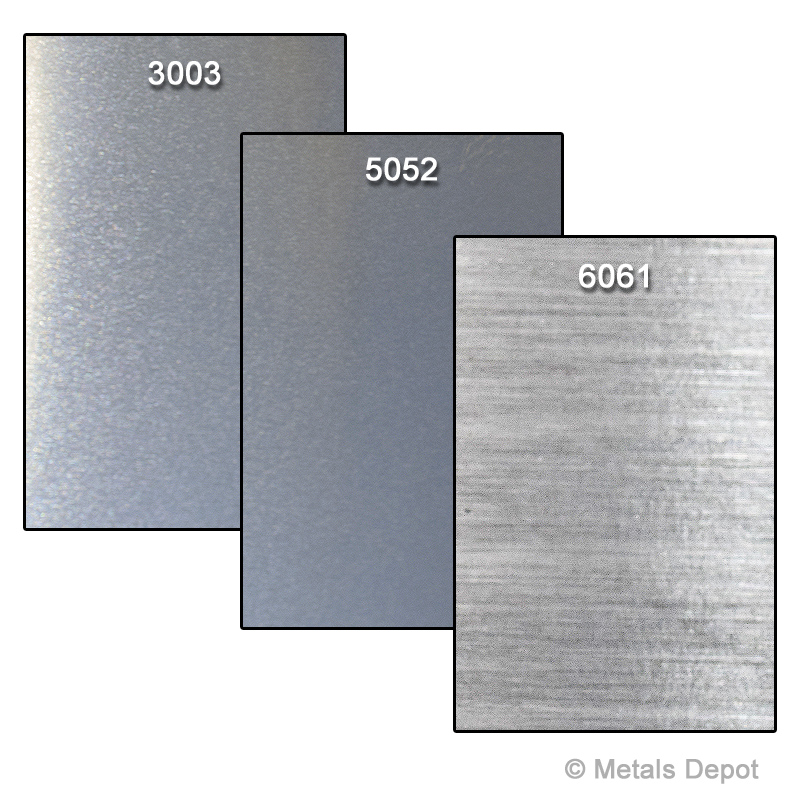

5052 aluminum data sheet. Like all the 5000 series high magnesium alloys 5052 has a fairly high strength and is hardenable to a significant degree by cold working enabling a series of h tempers. It also has very good weldability and good cold formability. It also has very good weldability and good cold formability. Alloy 5052is a non heat treatable 2 magnesium 0 25 chromium alloy commonly available in flat rolled coil sheet and plate from a wide range of producing mills.

Tensile strength range is 31 to 44 ksi. Aluminium alloy 5052 contains nominally 2 5 magnesium 0 25 chromium. 5052 has excellent workability weldability and corrosion resisitance. 5052 is not heat treatable but is stronger than most of the 5xxx series of aluminums.

The 5052 aluminum sheet is highly resistant to corrosion it is an alloy that contains 0 25 percent chromium and 2 5 percent magnesium. Typical applications include architecture general sheet metal work heat exchangers. It also has the low density and excellent thermal conductivity common to all aluminium alloys. Overview 5052 is the aluminum alloy most suited to forming operations with good workability and higher strength than that of either 1100 or 3003.

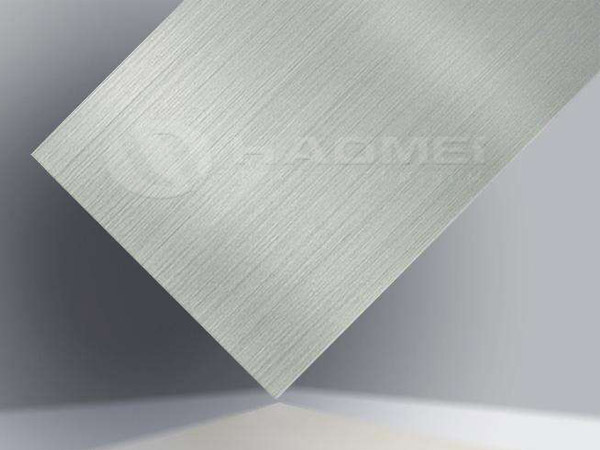

Aluminum 5052 h32 for extreme corrosion resistance since corrosion resistant 5052 aluminum plate and 5052 aluminum sheet provides a light weight high strength and attractive finish it is perfectly suited for a wide range of marine applications including ship building fuel tank assembly and oil line manufacturing. Download pdf aluminium alloy 5052 in h32 temper has very good corrosion resistance to seawater and marine and industrial atmosphere. It has good workability medium static strength high fatigue strength good weldability and very good corrosion resistance especially in marine atmospheres. It is a medium to high strength alloy with a strength slightly higher than 5251 and a medium to high fatigue strength.

It s widely used because of its formability and durability.