4340 Steel Data Sheet

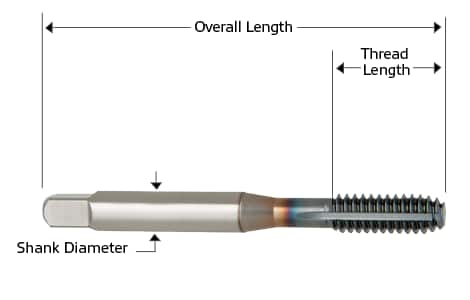

Typical applications include bolts screws and other fasteners.

4340 steel data sheet. Aisi 4340 steel can also be produced as light plates and castings. In addition the nickel in alloy 4340 increases hardenability of the steel. Technical specification of sae aisi uns system standard alloy structural steel aisi 4340 data sheet sae 4340 chemical compositions aisi 4340 mechanical properties from steelmaking esr melted blooming hot forging hot rolling heat treatment straightening 100 ultrasonic test cold working peeled or rough turned machining. For technical drawings and 3 d models click on a part number.

4340 high tensile steel 4340 is a 1 8 nickel chromium molybdenum high hardenability high tensile steel generally supplied hardened and tempered in the tensile range of 930 1080 mpa condition u rc 28 36. General characteristics lescalloy 4340 vac arc steel is a low alloy nickel chromium molybdenum steel capable of being escalloy 4340 vac arc steel is produced by the consumable electrode vacuum arc remelting process preferred ingot structure. Characterised by high strength and toughness in relatively large sections. This specification is for a premium aircraft quality low alloy steel in the form of bars forgings mechanical tubing and forging stock.

Atlas 4340 is a nominally 1 8 percent nickel chromium molybdenum low alloy steel of high hardenability with high strength and toughness in relatively large sections achieved with a quench and temper heat treatment. 4340 alloy steel also known as aisi 4340 is a low alloy steel with high toughness in an annealed state. Certificates with a traceable lot number are available for these products. Technical data sheet alloy e 4340 is a widely used deep hardening constructional steel.

Download certificates from activity after your order ships. Due to e 4340 s high alloy content it obtains a uniformed hardness by heat treatment. 4340 steel is mainly iron based with nickel being the other major chemical property. The inclusion of nickel in alloy 4340 helps simplify heat treatment.

4340 var ams 6414 is a low alloy chromium nickel molybdenum steel capable of being heat treated to high strength levels. The high fatigue strength makes e4340 ideal for highly stress parts as it maintains it s strength and hardness at elevated temperatures. An additional grade of alloy 4340 is alloy e 4340. 4340 alloy steel is characterized by its outstanding ductility formability and weldability rendering it an excellent metal for a variety of structural applications and components including power transmission gears and shafts aircraft parts and machinery.

Alloy 4340 plate is another general purpose grade of steel used for industrial and machining applications.