303 Stainless Steel Spec Sheet

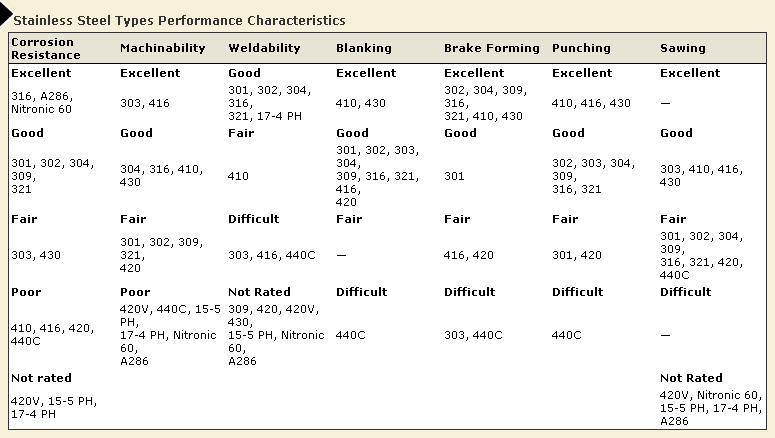

It is the free machining modification of the basic 18 chromium 8 nickel stainless steel.

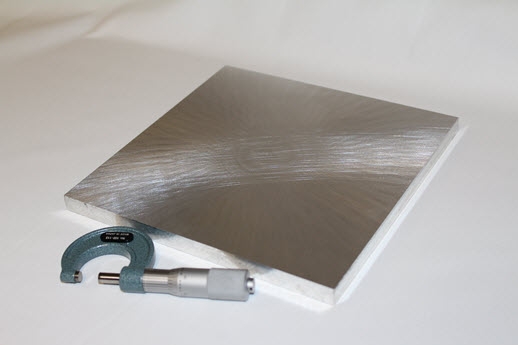

303 stainless steel spec sheet. Technical data sheet stainless steel 303 is a free machining stainless steel. Stainless steel 303 is widely used in the screw machine industry as well as for use in shafts valves and fittings. Type 303 is a non magnetic stainless steel which is not hardenable by heat treatment. The alloy has a sulfur addition which assists in breaking up turnings while reducing drag on the cutting tool when compared to the machining characteristics of the conventional 18 8 stainless steels.

En 1 4305 303 stainless steel provides good oxidisation resistance in intermittent service to 760 c 1400 f and continuous service to 870 c 1 598 f the use of 303 stainless steel is not recommended in the range of 425 860 c 797 1580 f due to carbide precipitation. Due to the addition of sulfur this 18 8 chrome nickel stainless steel has enhanced machinability where before it was tough and difficult to machine. 303 ss is a free machining austenitic stainless steel that is used primarily for parts requiring machining grinding or polishing. 303 is the perfect grade stainless steel to be used in machining applications.

In extreme oxidizing atmospheres irregular scaling may be encountered particularly above 1400 f. See specific product page for unique sizes. In stock and ready to ship. Choose from our selection of 303 stainless steel including over 600 products in a wide range of styles and sizes.

Grade 303 stainless steel has good resistance to oxidation when intermittently exposed to temperature up to 760 c temperatures. Chemical composition of 303. Typically 303 can be found used in shafts nuts bolts with gears in aircraft fittings316l grade stainless steel is one of the more common austenitic stainless steels. Alloy 303 uns s30300 is an austenitic stainless steel developed for applications requiring extensive machining operations.

Alloy 303 was specially designed to exhibit improved machinability while maintaining good mechanical and corrosion resistant properties due to the presence of sulfur in the steel composition alloy 303 is the most readily machineable austenitic stainless steel. This however is not recommended as 303 is sensitive to carbide precipitation with continuous use at 425 860 c. 303 has good resistance to oxidation at temperatures up to 1700 f. However the sulfur addition does lower alloy 303 s corrosion resistance to below that of alloy 304.

The additional sulfur present in 303 assists in breaking up turnings which reduce drag on the cutting tool. 303 is susceptible to sensitisation.

%20copy.jpg)