302 Stainless Steel Material Property Data Sheet

Austenitic non magnetic extremely tough and ductile 302 stainless steel is one of the more common chrome nickel stainless and heat resisting steels.

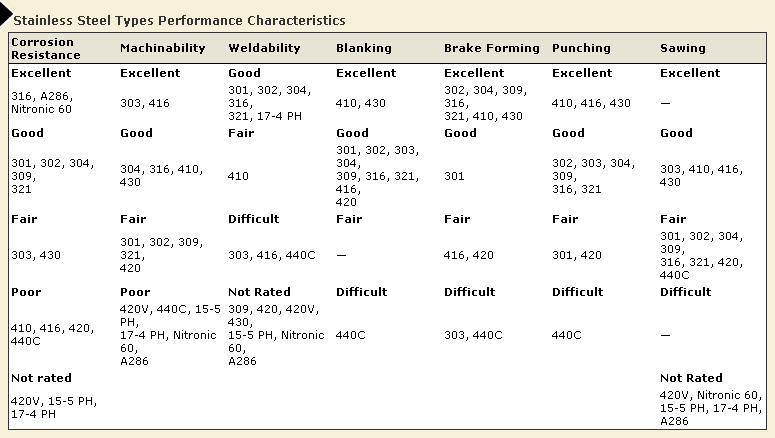

302 stainless steel material property data sheet. 302 stainless steel alloy data sheet alloy represents an excellent combination of corrosion resistance and fabricability. Types 302 304 304l and 305 stainless steels are variations of the 18 percent chromium 8 percent nickel austenitic alloy the most familiar and most frequently used alloy in the stainless steel family. Alloy 302 is a variations of the 18 chromium 8 nickel austenitic alloy which is the most familiar and the most frequently used in the stainless steel family. Alloy 302 is usually used in its annealed condition and has a high ease of fabrication and formability.

Alloy 302 is an austenitic stainless steel which has better corrosion resistance than alloy 301. 302 stainless steel unverified data categories. 302 ss is non magnetic and it is not hardenable by heat treating. The alloy is not hardenable by heat treatment and in non magnetic in the annealed condition.

More corrosion resistant than type 301 and because of higher ni content does not work harden as quickly as type 301. T 300 series stainless steel. Alloy 302 is a slightly higher carbon version of 304 often found in strip and wire forms. Alloy 302 is used widely in equipment and utensils for processing and handling of food beverages and dairy products.

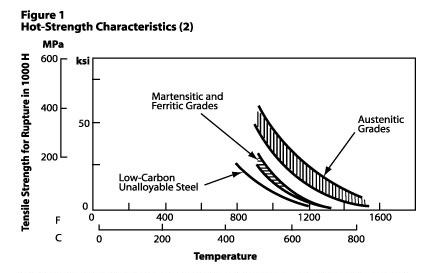

It is a tough ductile grade that demonstrates comparable corrosion resistance is non magnetic and is not hardenable by heat treatment. While it can be cold worked to increase hardness it will also cause it to become slightly magnetic. With it s higher nickel content alloy 302 does not work harden as quickly as alloy 301. Types 302 s30200 304 s30400 304l s30403 and 305 s30500 stainless steels are variations of the 18 percent chromium 8 percent nickel austenitic alloy the most familiar and most frequently used alloy in the stainless steel family.

Technical data sheet alloy 302 also know as 18 8 is an austenitic stainless steel it provides useful resistance to corrosion on a wide range of moderately oxidising to moderately reducing environments. Past users of 302 stainless are generally now using 304 alloy since aod technology has made lower carbon levels more easily attainable and economical. Cold working will dramatically increase its hardness and applications range from the stamping spinning and wire forming industry to food and beverage sanitary cryogenic and pressure containing. These alloys may be considered for a wide variety of applications where one or more of the following properties are important.

Each alloy represents an excellent combination of corrosion resistance and fabricability. Gibbs stocks a vast inventory of stainless steel spring wire in many alloys and diameters. 302 304 stainless steel wire datasheet provided by gibbs wire steel llc.