2mm Aluminium Sheet Bending

This doesn t sound like a lot but when you are drilling four holes to mate up to another piece its important.

2mm aluminium sheet bending. Move the sheet around inside the brake as needed to align the bend point with the internal edge of the clamp bar the side facing you. Create a long fracture line then progressively bend the sheet from one end to to the other. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools. You can also use a craft knife to mark soft metals such as aluminium.

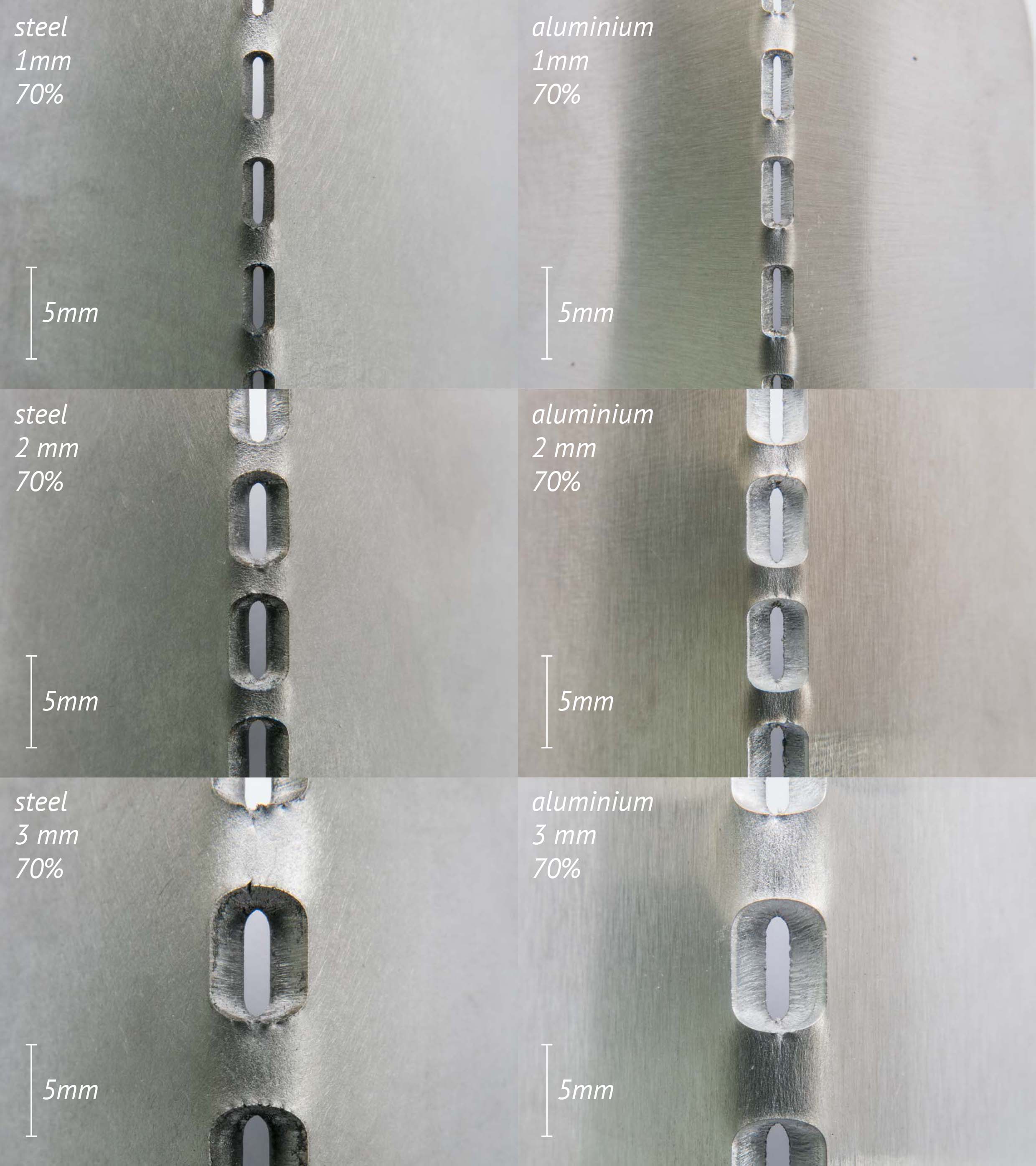

How to bend sheet metal without a brake. Place the fracture line over the edge of a table and bend the overhang slightly downwards. To keep it simple i also use a 2 mm inside radius. Material bend radii and minimum bend size charts please note.

After a few wiggles the sheet will fracture along the cut line leaving a clean break as shown in the above photos. With care and patience full size sheets of aluminium can be cut using this method. I can now see that the minimum flange length is 8 5 mm for such a bend so i have to keep it in mind when designing. The section of the sheet beneath the clamp bar will fold up and around this edge to produce the bend.

With a 2mm line you could be out of square by 2mm or the hole you just drilled is off 2mm. Adjust the edge of your sheet to set your desired bend line. Flip the sheet over and repeat. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

The required die width is 12 mm and tonnage per meter is 22.