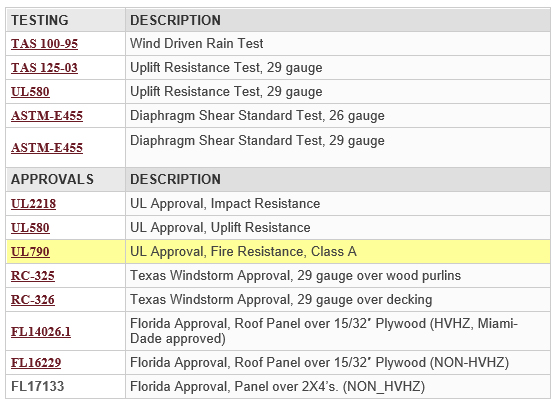

26 Gauge Sheet Metal Fire Rating

The ratings are for unsymmetrical walls that require ratings from both sides.

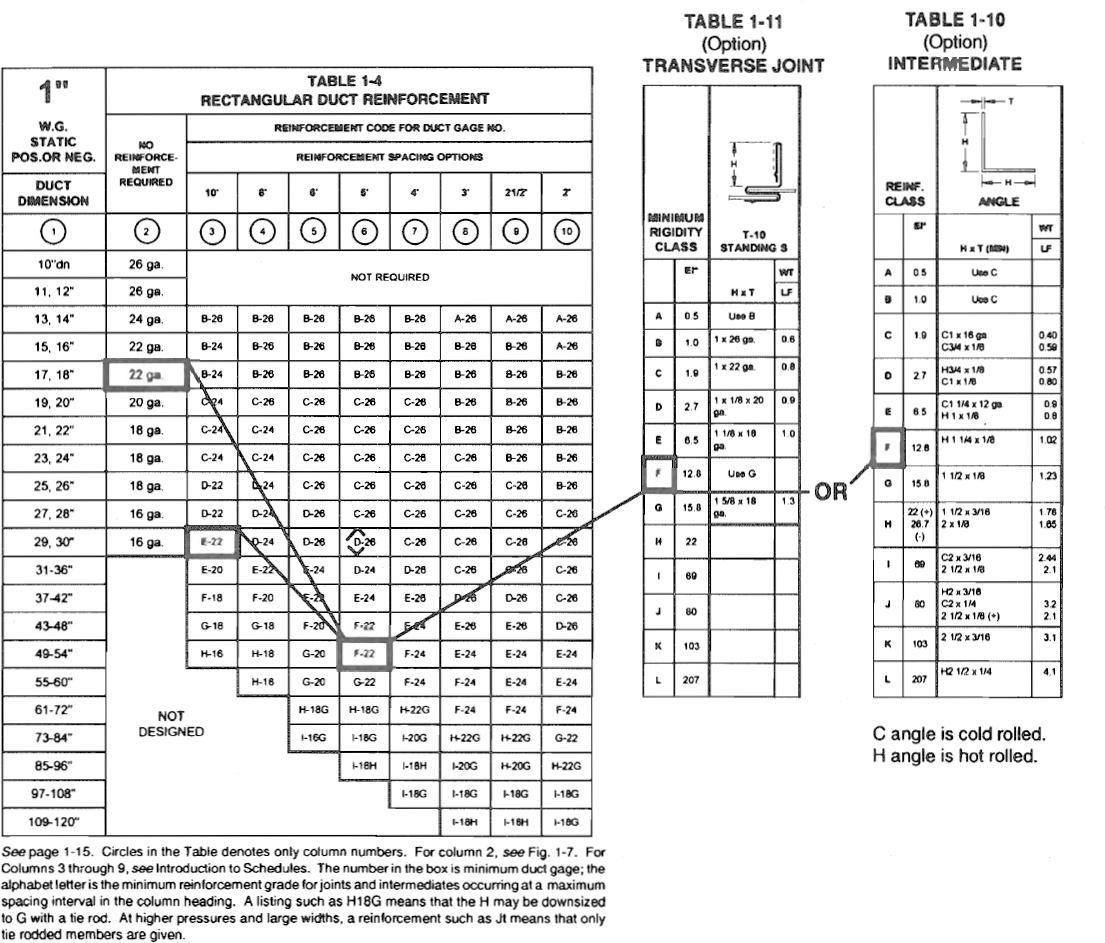

26 gauge sheet metal fire rating. To give a perspective on steel thickness differences from 29 gauge to 26 gauge the difference in thickness is 0045 of an inch. Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet. The code requirements for fire resistance of metal panels are logical and not overly burdensome. To help this blog will explain the gauge system and features a sheet metal gauge chart.

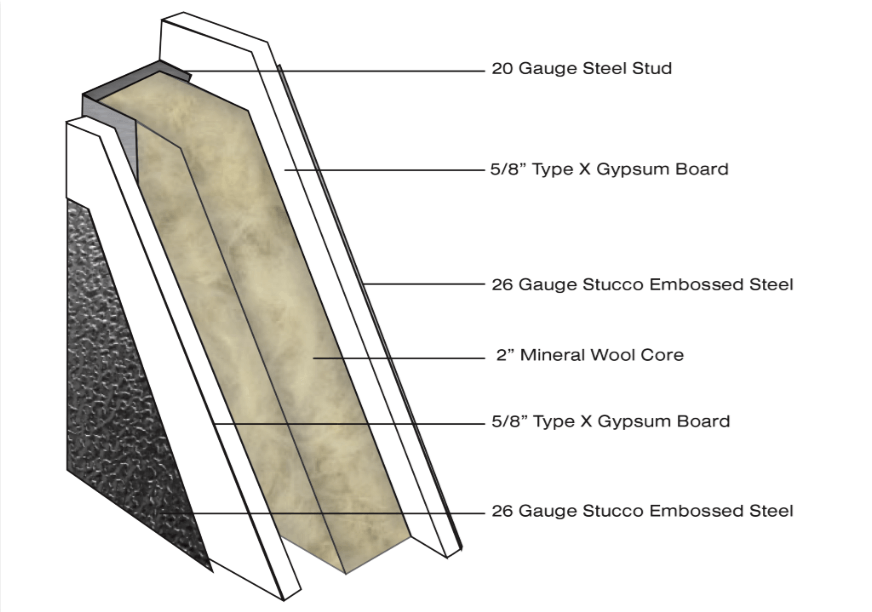

Fire ratings are based on an assembly. Sheet metal penetrations are used in rated assemblies and when correctly fire caulked. One sheet of 5 8 type x sheetrock has no fire rating. Fire resistance steel framing won t feed a fire fast facts.

The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material. V421 which pro vides 1 and 2 hour fire resistance ratings for exteri or walls in metal buildings. Building with fire safety in mind. 1 restrained beam rating based on the period of fire exposure where the beam sustains the applied design load but not more than twice the corresponding unrestrained beam rating and provided the later is 1 hour or.

On average wood structural members or framing rank third as the first ignited material in home fires according to the national fire protection association. The nonfire side of a fire rated assembly exceeds 325 degrees above its ambient temperature. Support spacing for 26 gauge steel deck. A specific field erected construction of an assemblage of materials designed to prevent the spread of fire through openings.

For 1 hour restrained assembly rating. Support spacing for 22 gauge 1 1 2 inch or 3 inch fluted steel deck. Most metal panel manufacturers have tested their roof assemblies and most if not all metal panels and shingles can be used in class a fire rated roof systems. Pole buildings are normally produced with a thinner roof and wall panel consisting of 29 gauge steel.

The mbma fire tests of exterior walls in 1997 resulted in a new uldesign no. The sheet metal and air. The thickness and number of the layers of type x gypsum wallboard are specified for each. When working with sheet metal it is common for the term gauge to be used someone unfamiliar with the gauge system may not understand what is meant by 18 gauge steel for example.

Astm e119 tests on loaded structural steel and composite steel concrete beams are always restrained and result in 2 ratings. But when it is used one on each side of a properly framed wall it can become a fire rated wall.