2024 Sheet Metal Bend Radius

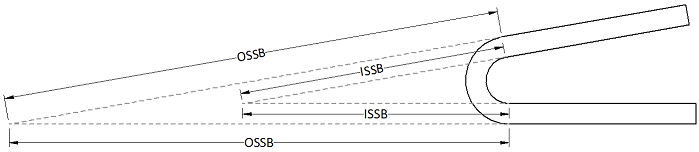

Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle.

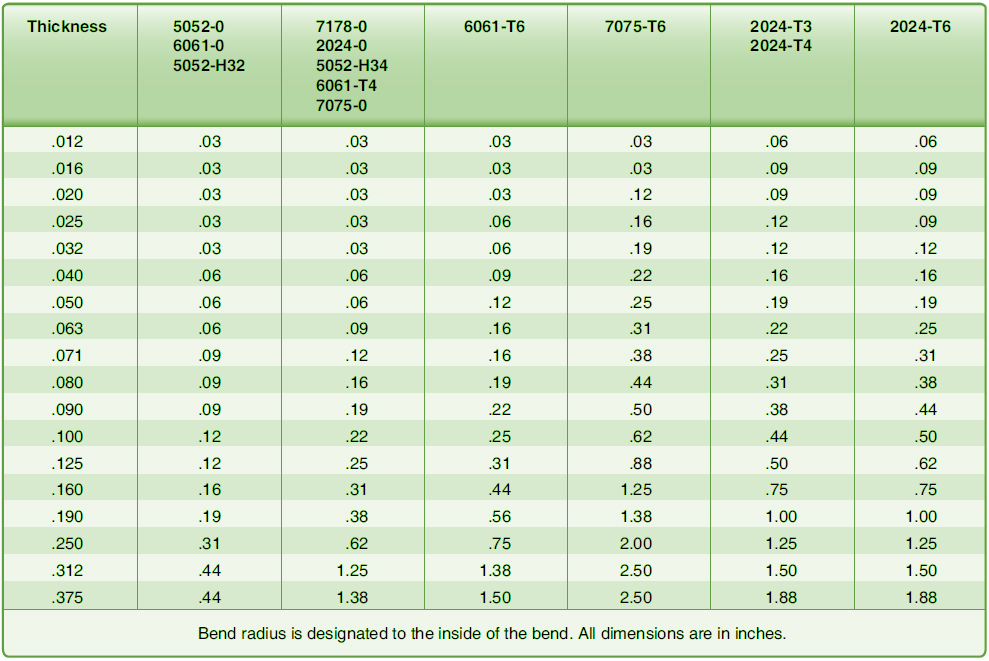

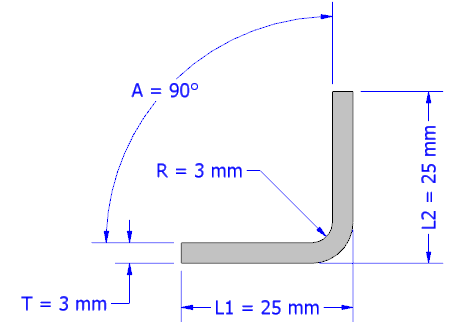

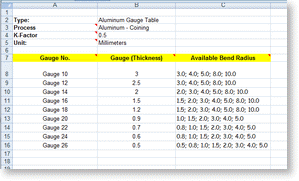

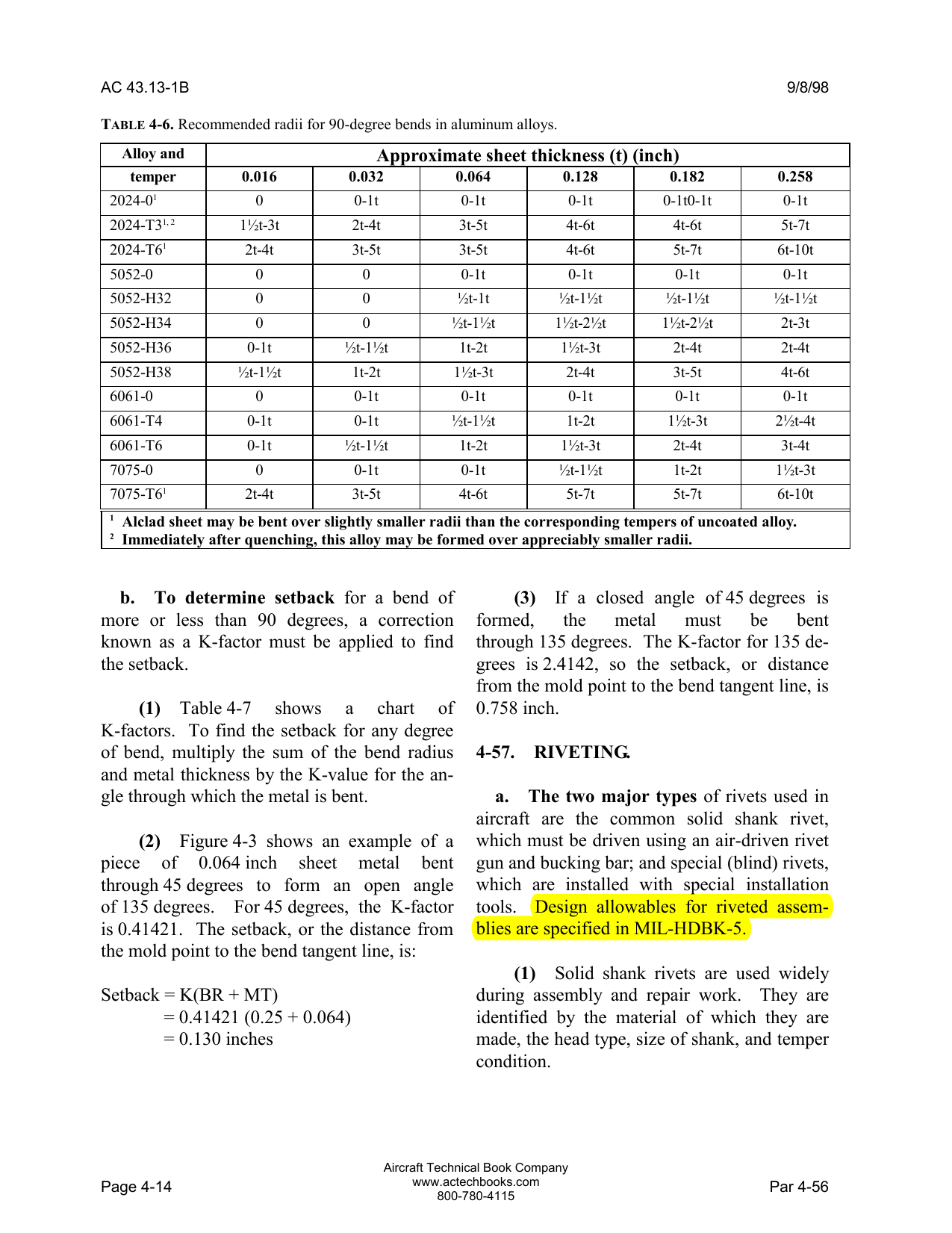

2024 sheet metal bend radius. Specifing a bend radius from here will help prevent hair line cracks. Use this document to choose values that are both manufacturable and meet your needs. For this layout example use the minimum radius chart in figure 2 to choose the correct bend radius for the alloy temper and the metal thickness. The minimum bend radius data shown in these charts is measured to the inside of the bend.

Table 1 preferred recommended 90 degree bend radii for various sheet metals. We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts. The material thickness will be measured in decimal form not by the gauge number. After a bending operation residual stresses will cause the sheet metal to spring back slightly.

The brake radius bars of a sheet metal brake can be replaced with another brake radius bar with a different diameter. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

For 0 040 2024 t3 the minimum allowable radius is 0 16 inch or 5 32 inch. Radii for various thicknesses expressed in terms of thickness t. Sheet metal bend radii if these guidelines are not followed more research and or some form of analysis may be requried. Aluminum minimum bend radii for 90 degree cold forming of sheet and plate.

The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance. 2024 t3 1020 1025 4130 ann. 3003 0 1100 0 6061 s0 5052 s0. It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

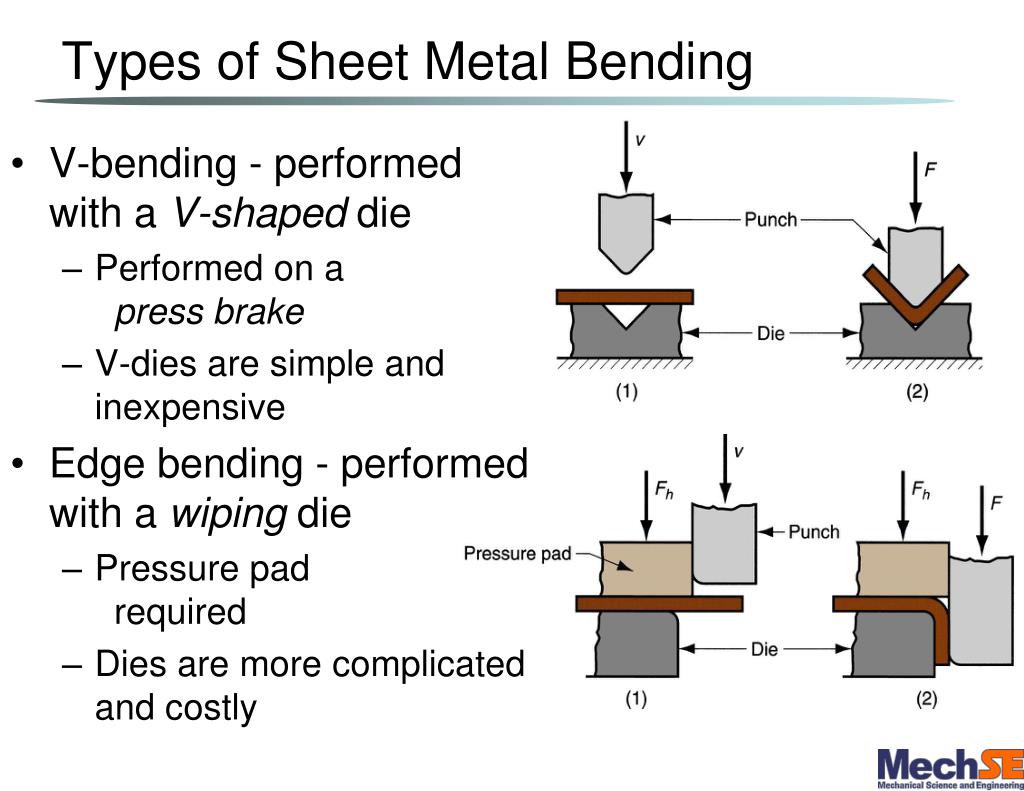

You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.