180 Degree Hem On Sheet Metal

That why we will be doing a separate implementation of hem as well.

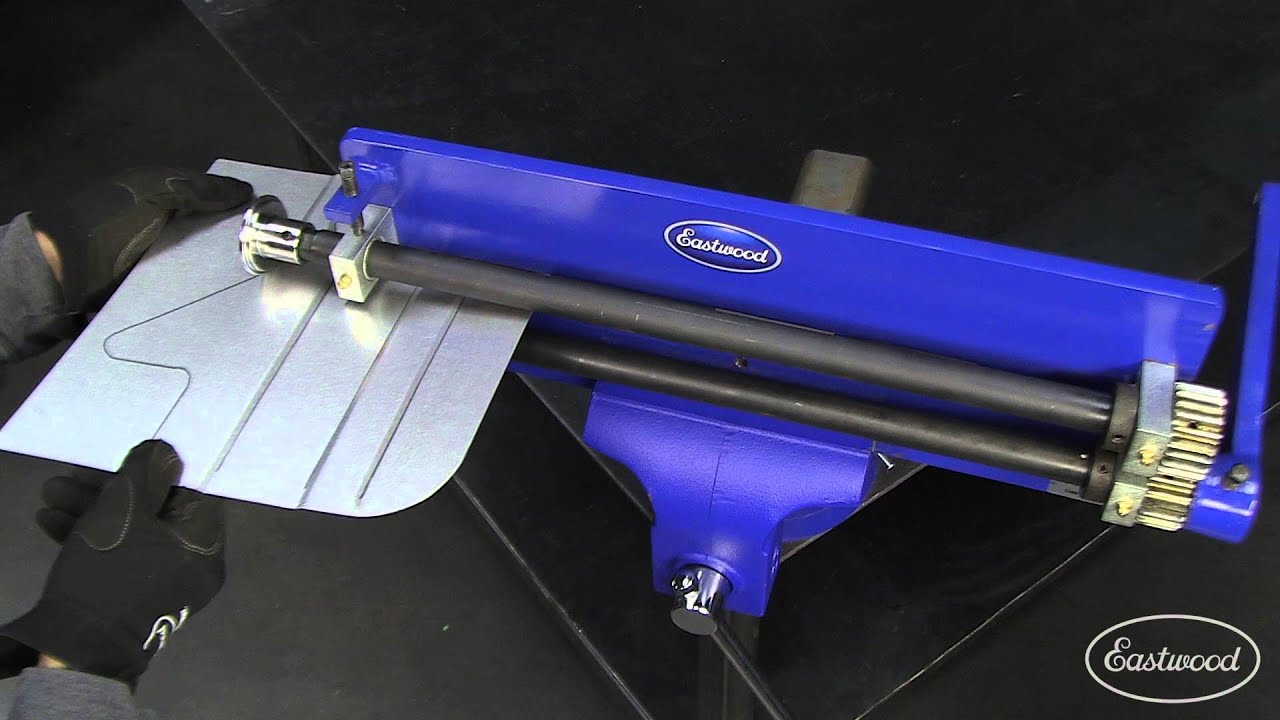

180 degree hem on sheet metal. Wuko 4010 in conjunction with any bending tool allows user to create 180 degree hems in sheet metal. If the hem has a radius greater than zero it resembles a u in cross section. With the lever in position 1 as the blank engages the indexing roll a pin drops into the first notch. Basically they dont work.

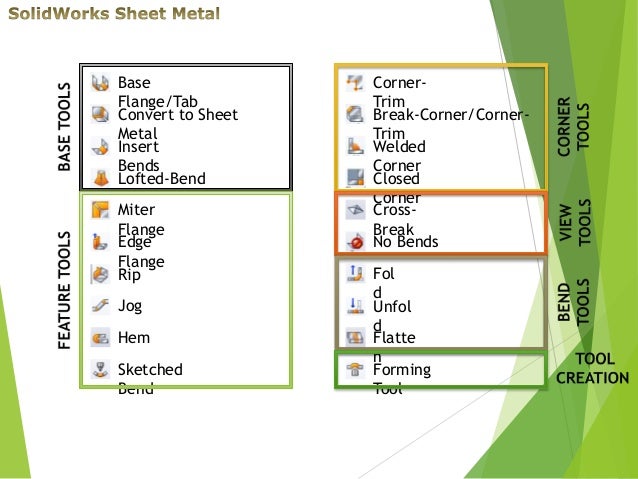

This appears to be something to do with hems and seams being 180 degree bends. This machine is standard equipped with no tooling in the center position and 2 sets of outboard shafts equipped with. Am i missing something here or are manual work arounds required when. Bend radii minimum bend sizes.

X 180 degree hem rolls for 20 26ga right side hem with 5 8 kick rolls left side seetk hem kick manual. In case the load is released and the material s springback results in a wrong angle it is simple to adjust by just applying some more pressure. Protocase tech tip video. The maximum bend height of this tool is 3 4.

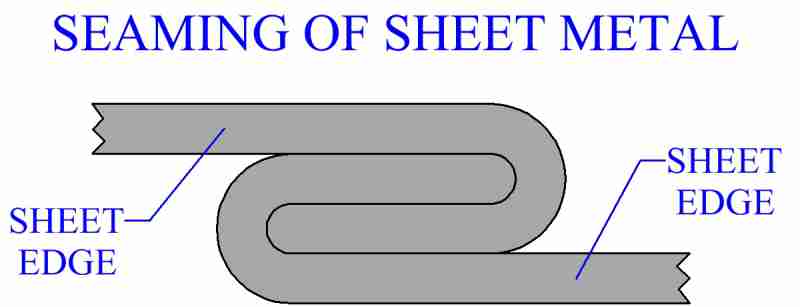

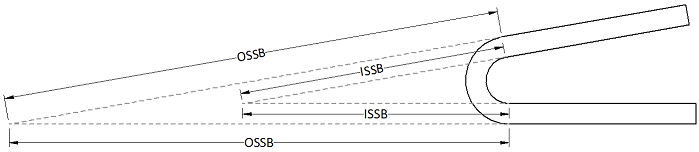

Let s begin by looking at the hem. 180 case would not fit the feature design. A ridge adjacent to the pin pre bends the material at its corner just enough to force the material into the hem forming rolls where the 180 degree hem is formed. A hem is a single 180 degree bend.

Some hems are closed basically a zero inside bend radius. Length of flange is measured from the virtual intersection of external walls. It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii. Limits on flange angle are 1 179 degrees.

They did and in some cases are still used. Though less accurate than bottoming or coining this kind of simplicity is the beauty of the method. If no flat section to the hem is evident it is simply an edge bead. Shop wuko bending products online at.

With this method you can get a result anywhere between 90 and 180 degrees. Unlike the u channels discussed in part iii the hem has only one bend instead of two. Working on the hem. There appears to be a limitation when it comes to using the miter flange and closed corner tools with hems and seams.