180 Degree Bend In Stainless Steel Sheet Without Cracking

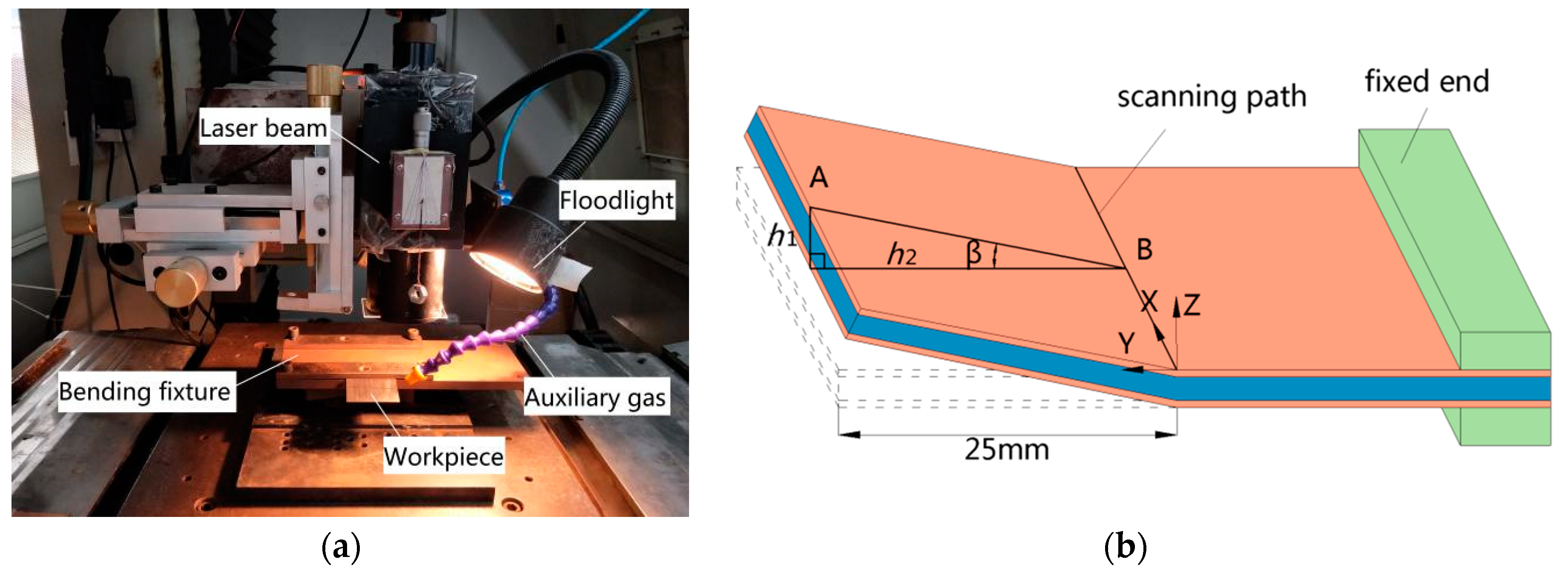

This makes bending stainless steel with common hand tools difficult and a sheet metal brake is often required although one technique to bend stainless steel using hand tools works well on shorter length bends.

180 degree bend in stainless steel sheet without cracking. Made from an american made 304 stainless and bent in the u s they are the best mandrel bends on the market. What makes our mandrel bends different is the tubing we start off with. Minimum bend radius annealed to 4 75 mm 0 5t for 180 degree bend cold rolled quarter hard 0 5t for 180 degree bend to 1 27 mm cold rolled quarter hard 1t for 90 degree bend. These buttweld 180 degree weld fittings are manufactured to very high tolerances via hydroforming.

Bend radii minimum bend sizes. Our stainless mandrel bends are the bends of choice for high end header fabricators. Easy to fabricate with they expand without cracking. This is done through the application of force on a workpiece.

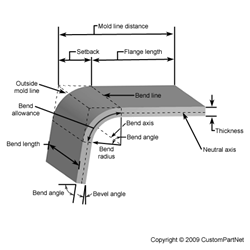

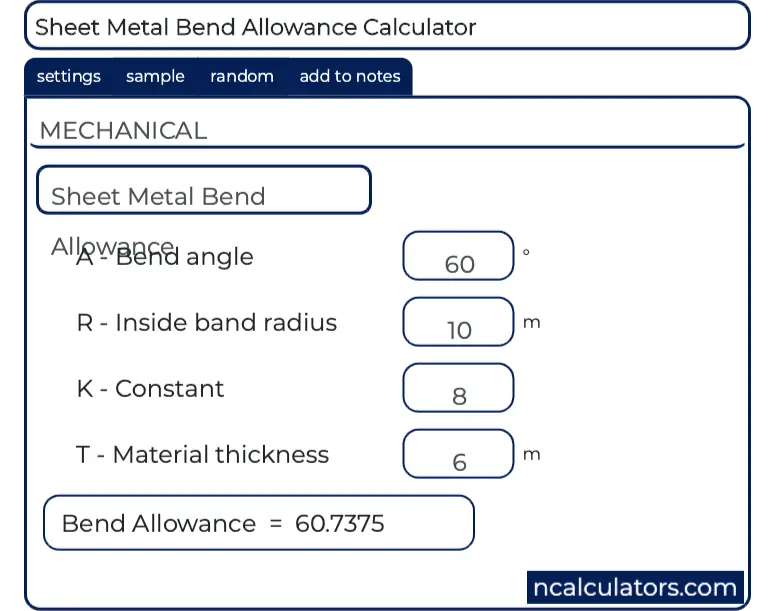

The following are typical bending limits for types 301 302 304 stainless steel. Bending is one of the most common sheet metal fabrication operations. The force must exceed the material s yield strength to achieve a plastic deformation. B2wul stainless steel 180 degree return bend weld fittings with tangent extensions are available with either a mill id od or a 32ra id od polished finish in your choice or 304 or 316l stainless steel.

As you bend a stainless steel sheet the bend area cold hardens increasing the amount of pressure required to finish the bend.