110 Copper Sheet Welding

Ercu typically contains 0 4 of si and mn with 0 8 of sn to aid fluidity.

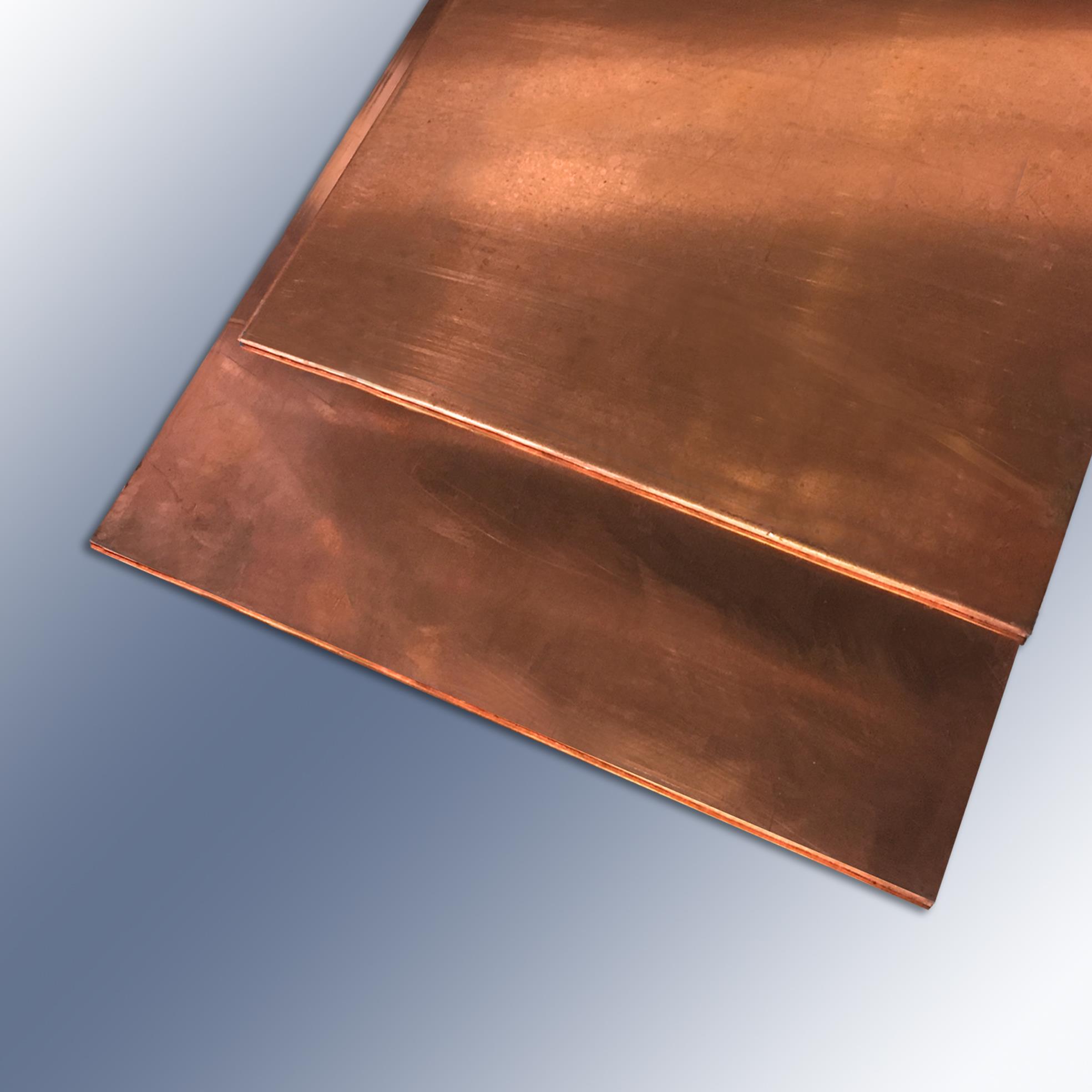

110 copper sheet welding. Etp copper 110 c110 c11000 astm b124 astm b152 astm b187 astm b370 din 2 0060 bs 2870 c101 bs 2874 c101 bs 2875 c101 en cw004a farmer s copper ltd. Copper sheets and bars offering high electrical conductivity and formability 110 copper is 99 9 pure. Contact industrial metal supply regarding our copper sheet and plate today. Copper sheet and plate 110 provides strength good corrosion resistance electrical conductivity and non sparking capabilities.

It is often necessary to raise the temperature level of the sheet in an area 6 0 to 12 0 in. It has the highest electrical conductivity of any metal except silver. The chemical composition contains minimum purity of 99 9 copper with approximately 0 04 oxygen. Copper sheets and bars offering high electrical conductivity and formability 110 copper is 99 9 pure.

Also known as etp copper it s often used in electrical applications such as for bus bars and wire connectors as well as for flashing gaskets and rivets. 152 4 to 304 8 mm away from the weld. It is a versatile alloy because of its resistance to corrosion high electrical and thermal conductivity and its aesthetic quality. Copper sheet and plate is often red and pink in color and is known for its malleability and ductility.

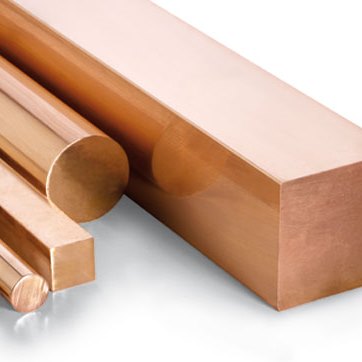

Copper alloy 110 c110 c11000 electrolytic tough pitch etp copper alloy 110 c110 c1100 electrolytic tough pitch etp is a very pure alloy of copper 99 9 min. Maintains an inventory c11000 electrolytic tough pitch etp copper in a variety of shapes including sheet plate bus bar square bar and round rod. Also known as etp copper it s often used in electrical applications such as for bus bars and wire connectors as well as for flashing gaskets and rivets. The two filler metals most often selected to weld the pure copper alloys are aws a5 7 ercu the c7 of the now superceded bs 2901 part 3 and ercusi a the old c9 of bs 2901.

Copper is an excellent choice for hot and cold forming applications as well as applications that require extensive machining. In welding copper sheets the heat is conducted away from the welding zone so rapidly that it is difficult to bring the temperature up to the fusion point.