09 Aluminum Sheet Deep Drawn

We then cut the metal down to 48 diameter blanks.

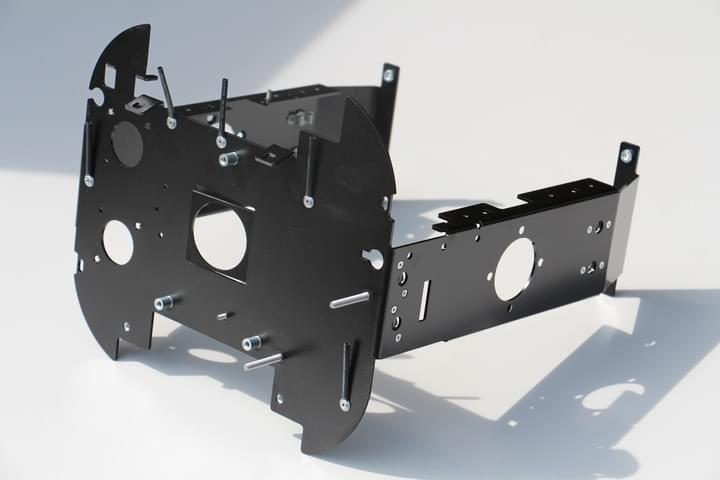

09 aluminum sheet deep drawn. We have over 25 000 standard shapes and sizes of deep drawn metal enclosures available with little to no tooling costs. Deep drawing is the most important process of shaping sheet where largely deformed metal sheets are turned into the hollow parts. It doesn t matter if you making an automobile hood or a deep drawn cup. Ultra deep drawing press processing.

See more ideas about deep drawing sheet metal work metal welding. Aluminum stamping uses mechanical presses and dies to form sheet metal into parts. The aluminum stamping process deep drawn stamping is a viable forming method when surface abrasion is a concern and is mainly employed for larger production runs and long term applications. Deep drawing is a process in sheet metal forming by the mechanical action of a punch.

Dec 1 2016 deep draw metal stamping deep drawing stamping parts sheet metal deep drawing parts. Many controlling factors contribute to the success of an aluminum stamping and many of those factors are controlled to a great degree by the mechanical properties of the aluminum sheet. Benefits of deep drawn aluminum. Design for deep drawing sheet metal stamping.

Deep drawn seamless enclosures we can help you engineer your custom deep drawn or fabricated enclosures from start to finish out of materials such as cold rolled steel stainless steel brass copper aluminum and more. Experimentally several laboratory methods are utilized to assess the ductility of the sheets. By means of the deep drawing processes carbon steel and stainless steel products are developed by china deep drawing engineering drawing. The blank shape of metal is placed on the die and contact with the punch.

Our expert engineers can help you select the best metal for your application. When the metal specimen is flat piece of sheet metal used in forming and finish the product. Aluminum is rust resistant non magnetic and for the most part highly heat treatable. We can also source metal for you or use sheet metal or rolled metal you already own.

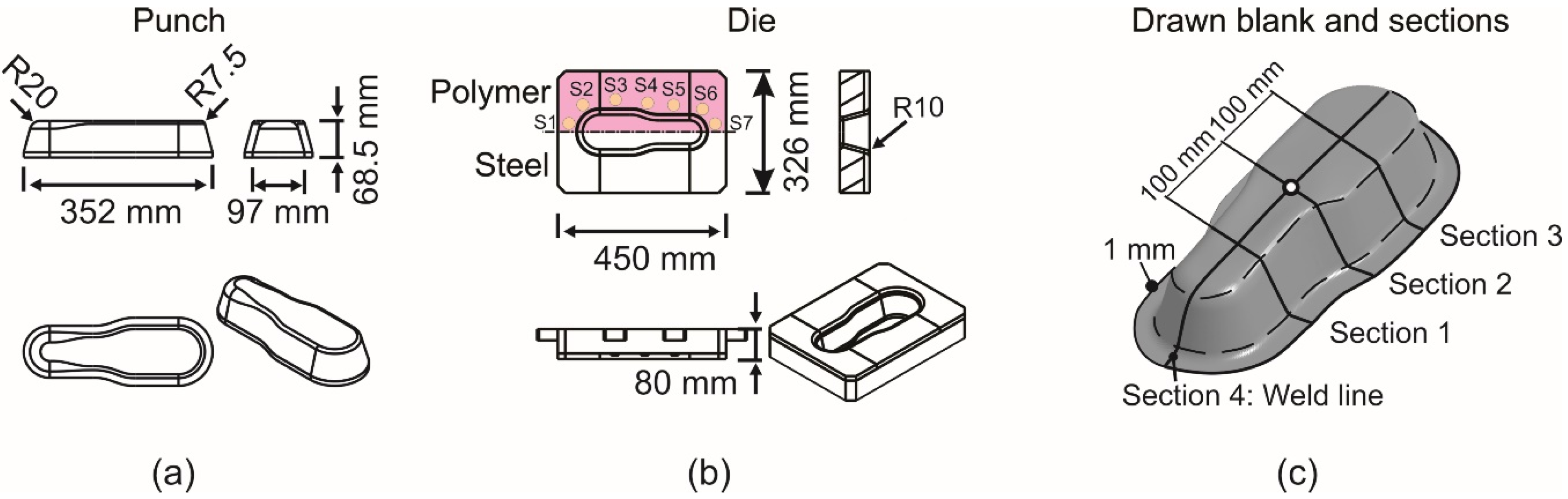

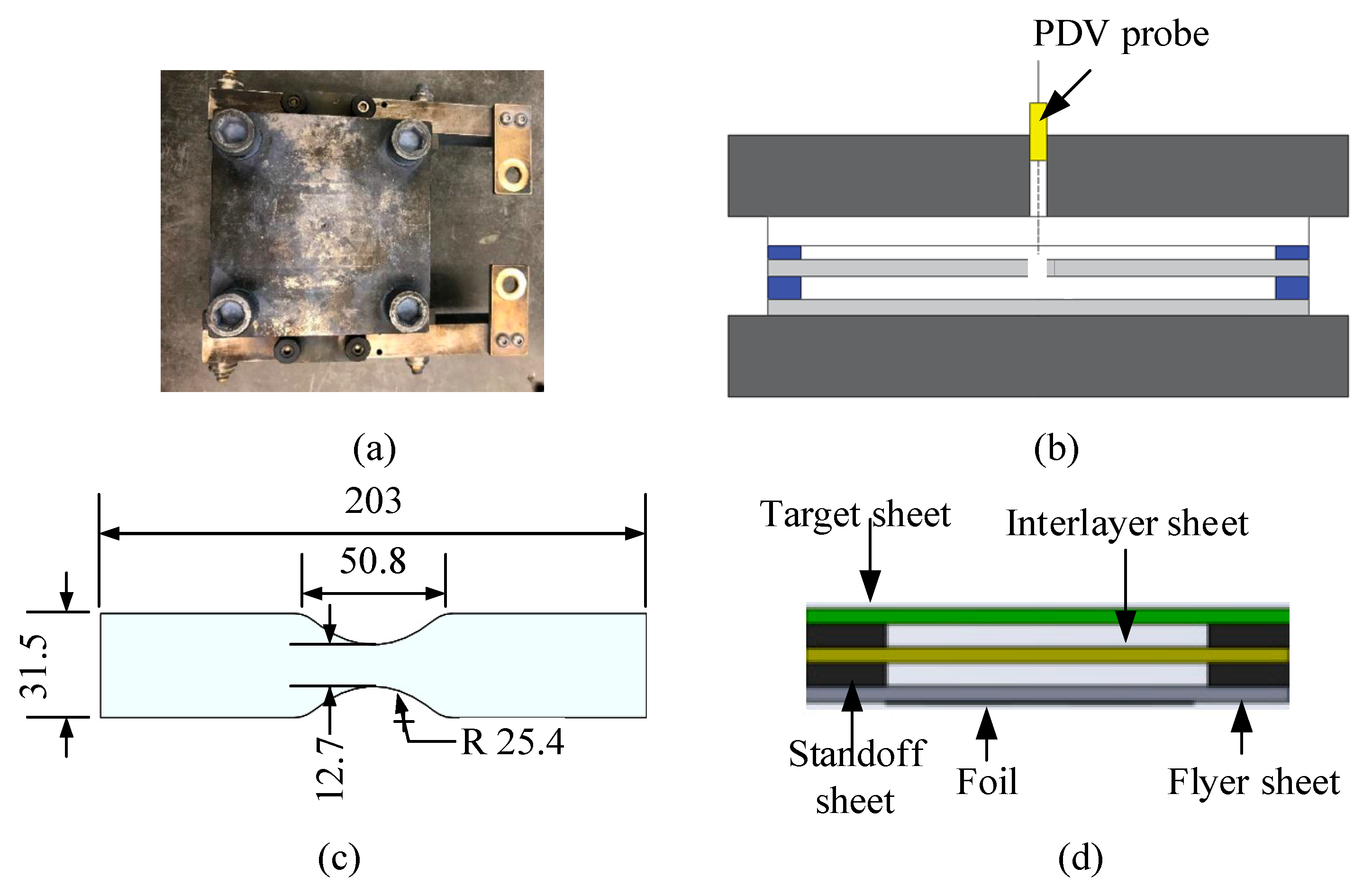

Ultra deep drawing press processing. These test methods include cylindrical cup deep drawing and deep shaping operations. The next step is preparing the blanks. A flat sheet metal blank is formed over a single rigid shape defning tool half by a flexible rubber diaphragm under uniform hydrostatic pressure.

Metal moulding and deep drawing. The first step in manufacturing a deep drawn part is choosing the alloy.